Modbus register map

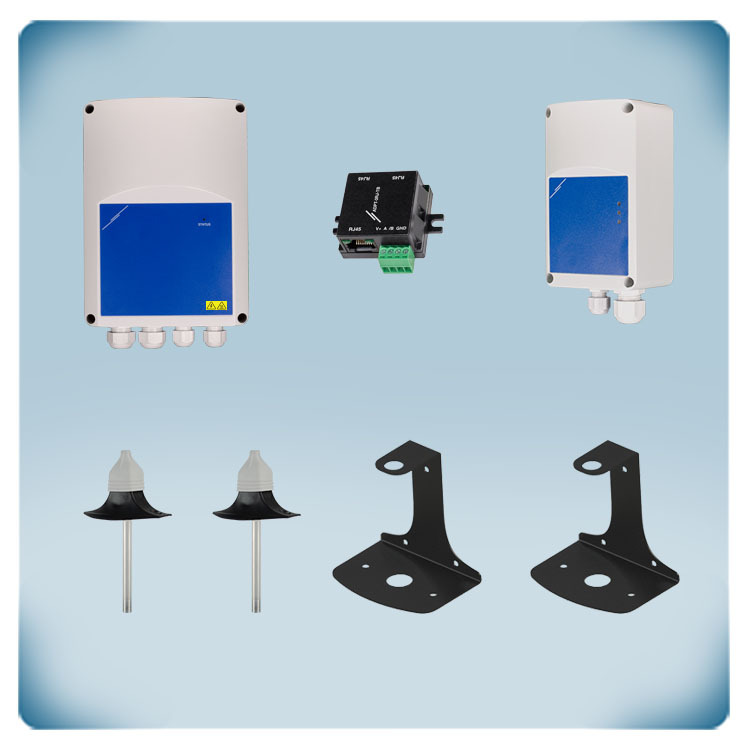

Destratification controller | Dual fan control 3 A

Solution description

Temperatures at the ceiling and floor level are measured by two temperature sensors with stainless steel probes 85 mm. The higher the difference between both temperatures, the higher the AC fan speed. The combined maximum speed per output is 3 A. There are two regulated outputs available. This destratification controller requires a separate internet gateway to connect the installation to SenteraWeb and to download firmware.

Documents

Additional specifications and description

Destratification to distribute the heat evenly

Warm air rises. In rooms with high ceilings, a layer of air builds up in layers with different temperatures. When warm air lingers just below the ceiling and the cold air is mainly at the bottom of the room, this creates an uncomfortable feeling. It also results in high heating costs, especially in the case of less well insulated buildings.

Destratification is the process of mixing these layers of air with different temperatures. Near the ceiling, the warm air accumulates. Closer to the floor are the colder layers of air. This causes an uncomfortable feeling for the residents and on top of that, a lot of heat is lost through the roof. Destratification fans or ceiling fans can solve this by mixing the layers of air with different temperatures. By mixing the air, the temperature under the ceiling and at the floor level is balanced. This creates a more pleasant feeling and requires less heating. In addition to significant energy savings, a better indoor air climate is created. Ceiling fan speed is regulated based on the difference between ceiling and floor temperatures. The higher the difference between both temperatures, the higher the fan speed. The delta temperature, minimum and maximum fan speed and all other settings can be adjusted via the Modbus holding registers. Typically, this solution is applied in large halls such as warehouses or manufacturing plants.

SenteraWeb HVAC cloud platform

Via the separate internet gateway (included in this solution), the controller can be connected to SenteraWeb. SenteraWeb is the HVAC cloud platform that offers remote control via a standard web browser. Connected devices can sent alarm messages when the measured temperatures exceed their ranges or when errors occur. Floor and ceiling temperatures can be logged and visualized in a diagram. Logged data can be exported. One or multiple users can have access to the connected device(s). Users can only see the values, configurators can see and adjust values of the Modbus Holding registers. Via the day-week scheduler, different ventilation regimes can be created.

Infinitely variable control for ceiling fans

This fan speed controller regulates the speed of ceiling fans by reducing the motor voltage. The voltage is reduced via phase angle control (TRIAC technology). This speed controller is therefore only suitable for voltage controllable motors. If you are not sure whether your motor is voltage controllable, it is best to contact the motor manufacturer. This speed controller works completely silently. The fan speed can be controlled with the knob on the front panel. Depending on the motor type, a humming motor noise may occur at low speed.

Modbus RTU communication

All devices exchange information via Modbus RTU communication. Digital temperature sensors are more accurate than passive temperature sensors. With passive temperature sensors, the measured value is influenced by the electrical resistance of the cable. This is not the case with digital sensors. Digital temperature sensors send the measured values via Modbus RTU communication. Modbus communication is more stable and reliable than a 0-10 Volt signal and it offers the possibility to use longer cables. All information from the connected devices is available, not just the measured values. If a problem occurs in one of the sensors, a detailed alarm notification can be sent.

Remarks, reviews & ratings