EU declaration conformity

Constant pressure controller | display | -125 to 125 Pa | PoM supply

Product description

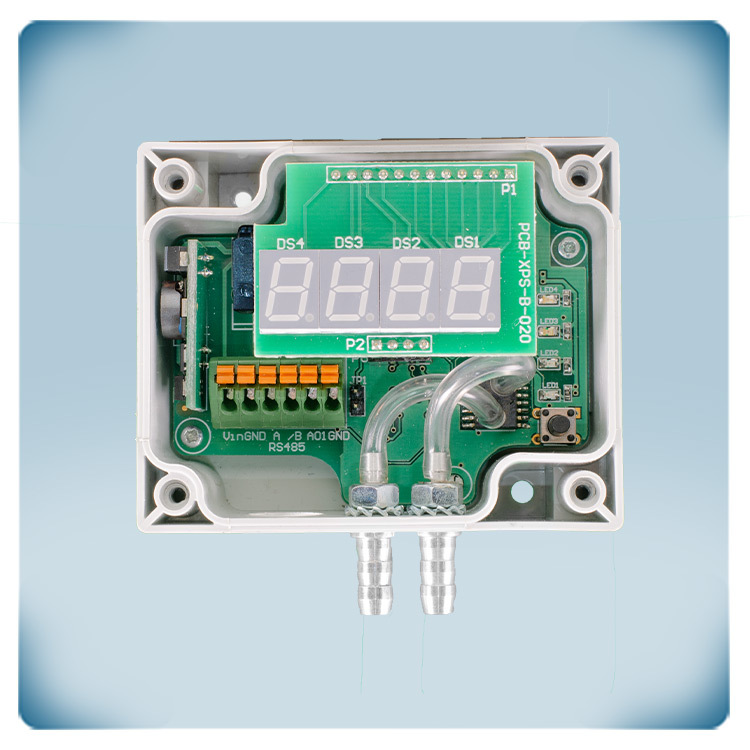

This is a differential pressure controller with a display, perfect for Variable Air Volume (VAV) fan systems. It operates within a range of -125 to +125 Pa.

For easy setup, it uses 24 VDC Power over Modbus (PoM), which provides both power and Modbus RTU communication through a single RJ45 socket.

The device can control either differential pressure or air volume flow. With an optional Pitot tube set, it can also control air velocity. It's designed to control EC fans, frequency inverters, or AC fan speed controllers via Modbus RTU communication.

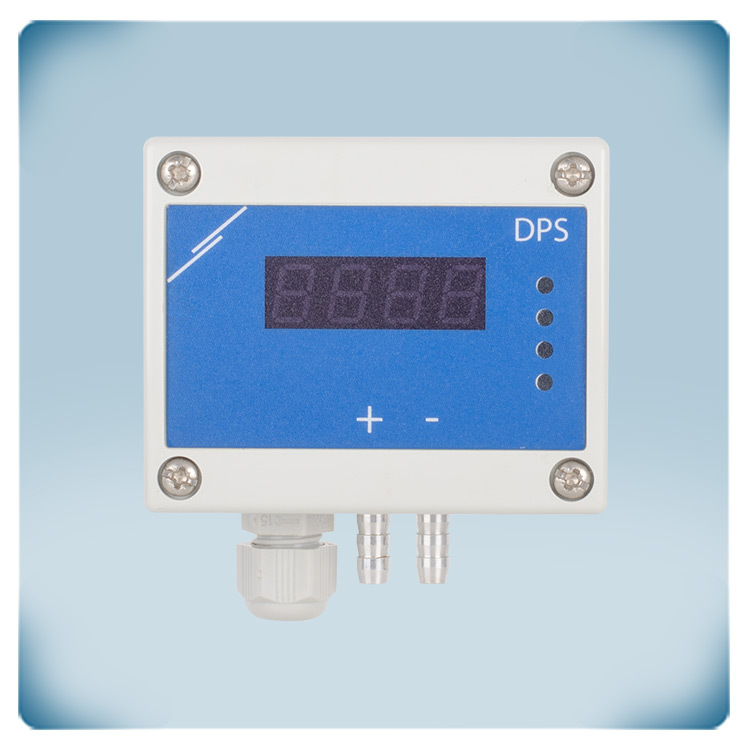

A 7-segment LED display and four LED indicators give a clear visual status of the device and its controlled values. The differential pressure setpoint and all other settings are fully adjustable via Modbus RTU.

Documents

Additional specifications and description

This differential pressure controller controls EC fans or AC fan speed controllers. It maintains the differential pressure [Pa] constant at the set point. The operating range is -125 to +125 Pa. It is also possible to control fan speed based on air volume flow [m³/hr] or air velocity [m/s]. To control air volume flow based on the K-factor of the fan, use the optional connection set type PSET-PVC-200 or PSET-QF-200. This connection set can also be used to control differential pressure. To control air volume flow based on the duct cross section [cm²] or air velocity [m/s], use the optional connection set type PSET-PTS-200 or PSET-PTL-200. The setpoint can be adjusted via Modbus RTU.

A 7-segment LED display shows the measured pressure, volume flow or air velocity. Additionally, green, yellow, and red LEDs provide visual cues for the measured values. Green indicates that the pressure is within the acceptable range, while yellow signifies an alert range. Red indicates that the differential pressure is outside the acceptable range. These LEDs also indicate the status of air volume flow or velocity. The second green LED shows the device status, illuminating when power supply and Modbus RTU communication are active.

This pressure controller regulates the speed of EC fans or AC fan speed controllers according to measured differential pressure, air volume flow or velocity. It adjusts fan speed to keep the measured value constant at the setpoint, which can be modified via Modbus RTU.

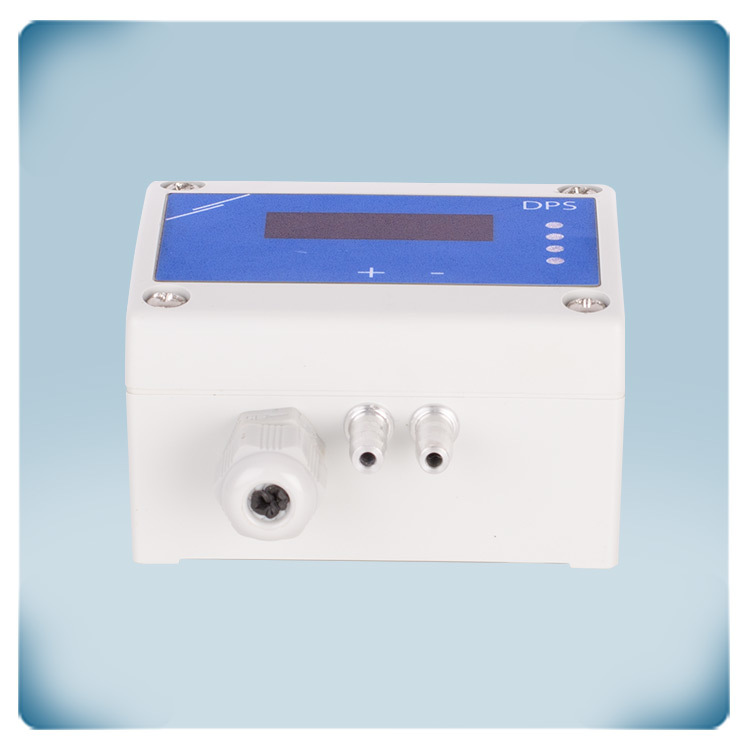

One RJ45 connector is all it takes to connect this sensor! Modbus RTU communication and 24 VDC power supply are connected via one cable - we call it Power over Modbus or PoM. All measured values are available via Modbus RTU communication.

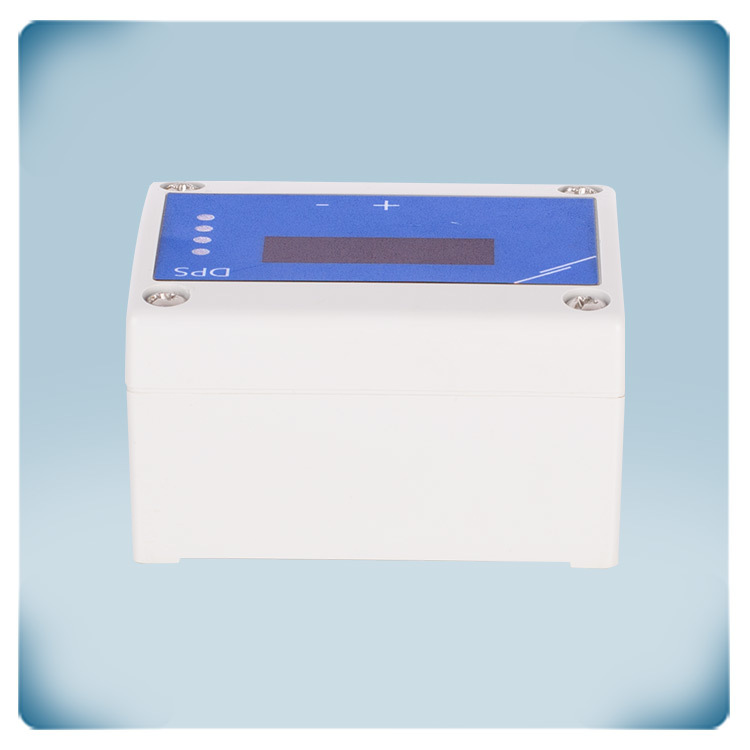

The enclosure is made of high-quality r-ABS VO (UL94) plastic. This material is heat resistant, very tough and offers good protection against impacts. The pressure connection nozzles are aluminium. The controller enclosure offers an IP65 protection against ingress of dirt and water. This pressure controller can be wall-mounted.

A common application for differential pressure controllers within this range involves regulating air pressure in settings such as staircases or cleanrooms. For instance, in staircases, maintaining a constant overpressure can prevent smoke infiltration during a fire.

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

Remarks, reviews & ratings