Schematic overview

NOT FOR SALE YET - Pressure control | AC fan

Solution description

Straightforward pressure-based exhaust air handling unit control.

This solution involves a fan with AC 400 V motor and maximum current 9,5 A. On/off air damper actuator control.

Documents

Additional specifications and description

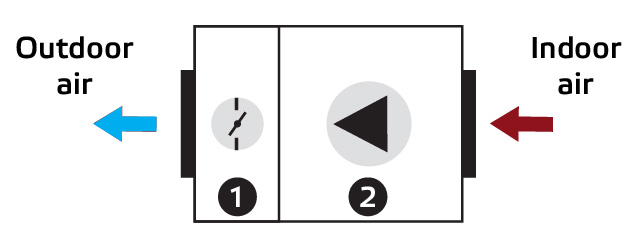

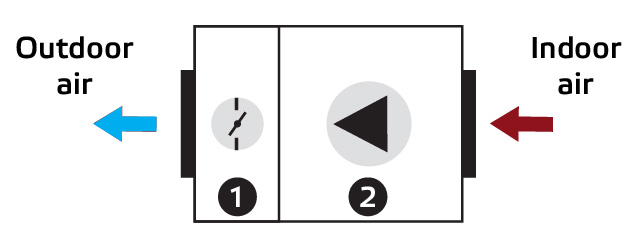

This solution is designed to monitor and control air handling unit that is shown on schematic below:

Air handling unit consists of two parts, which are exhaust air damper (1) and exhaust fan (2).

Control logic description

The operation of the air handling unit is designed to be automatic and relies on sensor readings to ensure precise and efficient performance. By utilizing predefined logics for different components of the AHU, the control system optimizes the overall operation.

Important aspect of the control logic is the timing of the exhaust air damper. It is programmed to open 30 seconds prior to the start of the exhaust fan. This timing is crucial, especially for AHUs with high airflow, as it helps prevent potential damage to the air damper by providing proper air pressure equalization.

The control system offers flexibility in controlling the speed of the exhaust fan. This solution has the option to control the fan speed either manually or automatically using a frequency inverter FI-E-44095E2. This feature allows for precise adjustment of the fan speed to match the specific requirements of the HVAC system.

To maintain optimal fan operation, the control system incorporates a differential pressure transmitter HPS-M-1K0-2. This transmitter continuously monitors the pressure difference across the system and regulates the fan accordingly. In the event of a mechanical failure, such as fan jamming or bearing breakdown, the control system detects the absence of pressure drop and initiates a series of steps to address the issue. It switches off the frequency inverter, closes the air damper, and promptly informs the user about the error. This proactive approach ensures that any mechanical failures are promptly addressed, minimizing downtime and potential damage to the AHU.

In automatic mode, the HPS-M-1K0-2 can be utilized to maintain a specific pressure difference as required. By continuously monitoring and adjusting the fan speed based on the pressure differential, the control system ensures consistent and reliable performance of the AHU, even in varying operating conditions.

System configuration

The system configuration includes a network gateway DIG-M-2, which serves as a connection point for users to access the online HVAC platform SenteraWeb. This gateway provides users with convenient remote access to the platform, allowing them to monitor data and adjust settings of the connected HVAC devices from anywhere, using either an Ethernet cable or a Wi-Fi network. Moreover, SenteraWeb offers data logging functionality, allowing users to record and analyze various operational parameters of the AHU. This data logging capability provides valuable insights into the performance of the system, enabling users to identify trends, diagnose potential issues, and optimize the overall operation of the AHU.

Air handling unit consists of two parts, which are exhaust air damper (1) and exhaust fan (2).

Control logic description

The operation of the air handling unit is designed to be automatic and relies on sensor readings to ensure precise and efficient performance. By utilizing predefined logics for different components of the AHU, the control system optimizes the overall operation.

Important aspect of the control logic is the timing of the exhaust air damper. It is programmed to open 30 seconds prior to the start of the exhaust fan. This timing is crucial, especially for AHUs with high airflow, as it helps prevent potential damage to the air damper by providing proper air pressure equalization.

The control system offers flexibility in controlling the speed of the exhaust fan. This solution has the option to control the fan speed either manually or automatically using a frequency inverter FI-E-44095E2. This feature allows for precise adjustment of the fan speed to match the specific requirements of the HVAC system.

To maintain optimal fan operation, the control system incorporates a differential pressure transmitter HPS-M-1K0-2. This transmitter continuously monitors the pressure difference across the system and regulates the fan accordingly. In the event of a mechanical failure, such as fan jamming or bearing breakdown, the control system detects the absence of pressure drop and initiates a series of steps to address the issue. It switches off the frequency inverter, closes the air damper, and promptly informs the user about the error. This proactive approach ensures that any mechanical failures are promptly addressed, minimizing downtime and potential damage to the AHU.

In automatic mode, the HPS-M-1K0-2 can be utilized to maintain a specific pressure difference as required. By continuously monitoring and adjusting the fan speed based on the pressure differential, the control system ensures consistent and reliable performance of the AHU, even in varying operating conditions.

System configuration

The system configuration includes a network gateway DIG-M-2, which serves as a connection point for users to access the online HVAC platform SenteraWeb. This gateway provides users with convenient remote access to the platform, allowing them to monitor data and adjust settings of the connected HVAC devices from anywhere, using either an Ethernet cable or a Wi-Fi network. Moreover, SenteraWeb offers data logging functionality, allowing users to record and analyze various operational parameters of the AHU. This data logging capability provides valuable insights into the performance of the system, enabling users to identify trends, diagnose potential issues, and optimize the overall operation of the AHU.

Remarks, reviews & ratings