EU declaration conformity

Warm air heater controller | 10 A

Product description

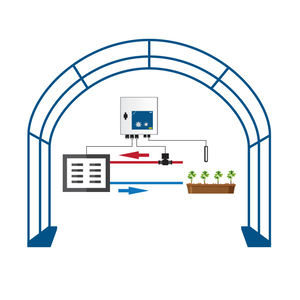

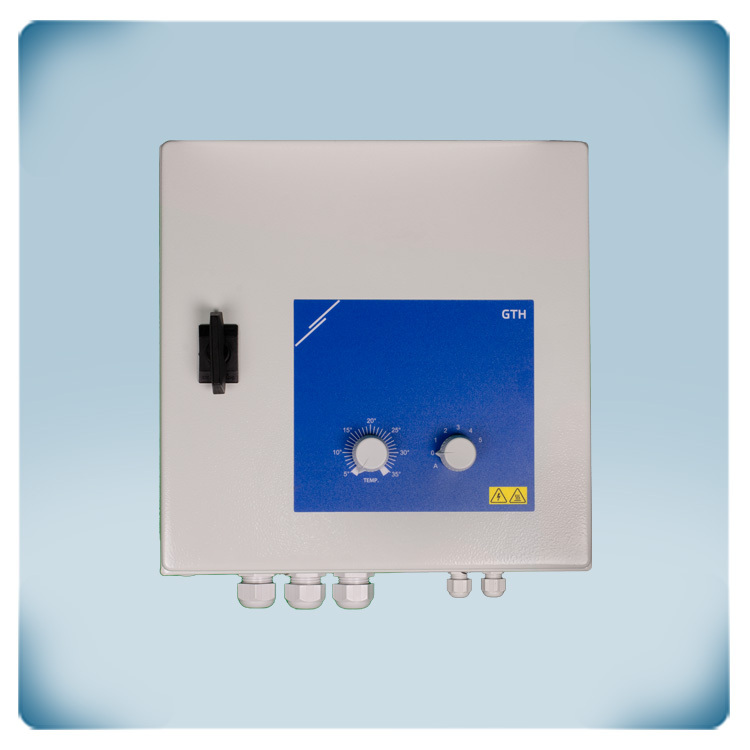

This temperature-controlled, 5-step fan speed controller is designed for single-phase motors with a maximum combined current of 10 A at 230 V AC. It operates with an external PT500 temperature probe and can control an external valve for hot water heating via its unregulated output.

The unit has both heating and cooling modes. In heating mode, the fan and output engage when the temperature drops, and the fan speed can be set manually or automatically. The system turns off when the temperature rises above the set point. This process is reversed in cooling mode.

Using autotransformer technology, the controller adjusts motor voltage in steps for quiet operation.

The device has an IP54-rated metal enclosure suitable for indoor surface mounting.

Documents

Additional specifications and description

How to measure ambient temperature?

The temperature probe used for this fan speed controller is a PT500 temperature sensor. PT500 sensors are platinum resistance thermometers that exhibit a change in resistance corresponding to the measured temperature. This allows the controller to accurately monitor the ambient temperature and make appropriate adjustments to the fan speed.

How does the 5-step fan controller respond to temperature in heating vs. cooling mode?

The controller features two modes of operation: heating and cooling. In heating mode, the fan is activated when the temperature falls below the set temperature. This helps to distribute warm air and maintain the desired temperature. In cooling mode, the fan is activated when the temperature exceeds the set temperature, aiding in dissipating heat and cooling the environment.

How Does Manual and Automatic Fan Speed Selection Work?

The fan speed can be adjusted manually using a rotary switch. By turning the switch, you can set the desired speed from the available 5-step options. Alternatively, there is an "Auto" mode where the fan speed adjusts automatically based on the temperature difference between the measured ambient temperature and the selected threshold temperature. The greater the difference, the higher the fan speed.

How Does the Unregulated Output Function in Heating and Cooling Modes?

The controller provides an unregulated output that operates in conjunction with the fan. In heating mode, the unregulated output is typically utilized to control a hot water supply valve or activate an electric heater. When the fan is running, the unregulated output is also activated. This ensures that the heater or valve operates simultaneously with the fan, maintaining a comfortable heating environment.

How does autotransformer technology ensure reliable fan speed control?

The fan speed controller employs autotransformer technology to control the motor voltage and subsequently adjust the fan speed. Autotransformer technology is used to control the motor voltage, which in turn adjusts the fan speed. An autotransformer works on the principle of electromagnetic induction, where a changing magnetic field induces a voltage in a nearby winding. In the fan speed controller, the autotransformer is connected to the fan motor. By adjusting the tap on the autotransformer, the voltage supplied to the motor can be changed, thereby altering the fan speed. The autotransformer has five taps to provide different voltage levels, corresponding to the desired speed settings. When a lower tap on the autotransformer is selected, the voltage supplied to the motor is reduced, resulting in a lower fan speed. Conversely, selecting a higher tap increases the voltage and speeds up the fan.

By utilizing autotransformer technology, the fan speed controller can smoothly adjust the motor voltage and control the fan speed in 5 steps. This allows for precise control over the airflow, ensuring optimal cooling or heating performance as required.

The use of autotransformers in fan speed control offers several benefits. It generates a sinusoidal motor voltage, which leads to quieter motor operation with reduced harmonics. The smooth voltage control also helps in extending the motor service life by minimizing stress and wear.

Why is the enclosure durable?

The fan speed controller is incorporated into a sturdy steel enclosure. This enclosure offers several advantages, including efficient heat dissipation, protecting the internal components from external factors, and providing durability. The efficient heat dissipation ensures that the controller operates within safe temperature limits, enhancing its reliability and lifespan. Additionally, the enclosure is designed with IP54 protection, which means it is resistant to dust and water ingress, making it suitable for indoor installations.

The temperature probe used for this fan speed controller is a PT500 temperature sensor. PT500 sensors are platinum resistance thermometers that exhibit a change in resistance corresponding to the measured temperature. This allows the controller to accurately monitor the ambient temperature and make appropriate adjustments to the fan speed.

How does the 5-step fan controller respond to temperature in heating vs. cooling mode?

The controller features two modes of operation: heating and cooling. In heating mode, the fan is activated when the temperature falls below the set temperature. This helps to distribute warm air and maintain the desired temperature. In cooling mode, the fan is activated when the temperature exceeds the set temperature, aiding in dissipating heat and cooling the environment.

How Does Manual and Automatic Fan Speed Selection Work?

The fan speed can be adjusted manually using a rotary switch. By turning the switch, you can set the desired speed from the available 5-step options. Alternatively, there is an "Auto" mode where the fan speed adjusts automatically based on the temperature difference between the measured ambient temperature and the selected threshold temperature. The greater the difference, the higher the fan speed.

How Does the Unregulated Output Function in Heating and Cooling Modes?

The controller provides an unregulated output that operates in conjunction with the fan. In heating mode, the unregulated output is typically utilized to control a hot water supply valve or activate an electric heater. When the fan is running, the unregulated output is also activated. This ensures that the heater or valve operates simultaneously with the fan, maintaining a comfortable heating environment.

How does autotransformer technology ensure reliable fan speed control?

The fan speed controller employs autotransformer technology to control the motor voltage and subsequently adjust the fan speed. Autotransformer technology is used to control the motor voltage, which in turn adjusts the fan speed. An autotransformer works on the principle of electromagnetic induction, where a changing magnetic field induces a voltage in a nearby winding. In the fan speed controller, the autotransformer is connected to the fan motor. By adjusting the tap on the autotransformer, the voltage supplied to the motor can be changed, thereby altering the fan speed. The autotransformer has five taps to provide different voltage levels, corresponding to the desired speed settings. When a lower tap on the autotransformer is selected, the voltage supplied to the motor is reduced, resulting in a lower fan speed. Conversely, selecting a higher tap increases the voltage and speeds up the fan.

By utilizing autotransformer technology, the fan speed controller can smoothly adjust the motor voltage and control the fan speed in 5 steps. This allows for precise control over the airflow, ensuring optimal cooling or heating performance as required.

The use of autotransformers in fan speed control offers several benefits. It generates a sinusoidal motor voltage, which leads to quieter motor operation with reduced harmonics. The smooth voltage control also helps in extending the motor service life by minimizing stress and wear.

Why is the enclosure durable?

The fan speed controller is incorporated into a sturdy steel enclosure. This enclosure offers several advantages, including efficient heat dissipation, protecting the internal components from external factors, and providing durability. The efficient heat dissipation ensures that the controller operates within safe temperature limits, enhancing its reliability and lifespan. Additionally, the enclosure is designed with IP54 protection, which means it is resistant to dust and water ingress, making it suitable for indoor installations.

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

Remarks, reviews & ratings