EU declaration conformity

Duct CO2 sensor | 24 VDC | Modbus RTU

Product description

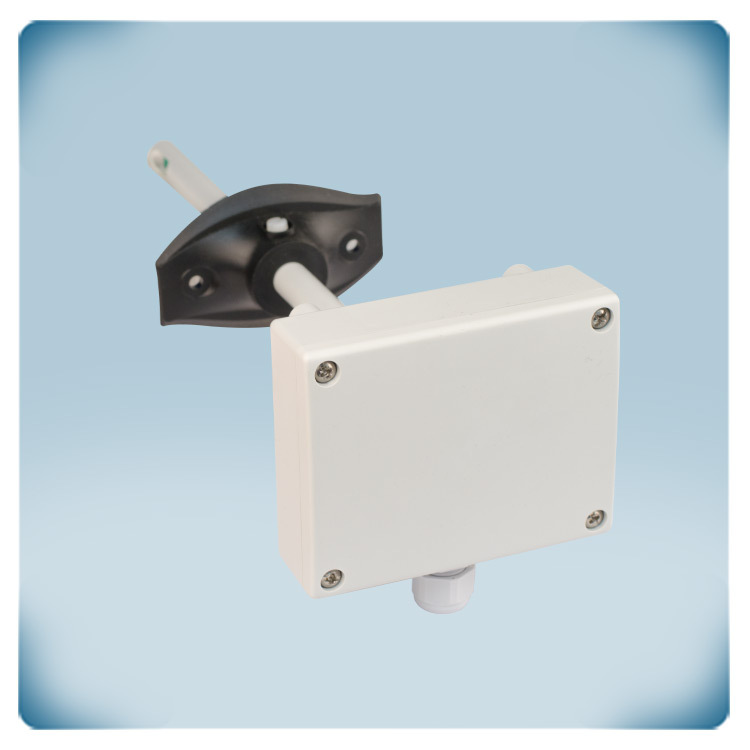

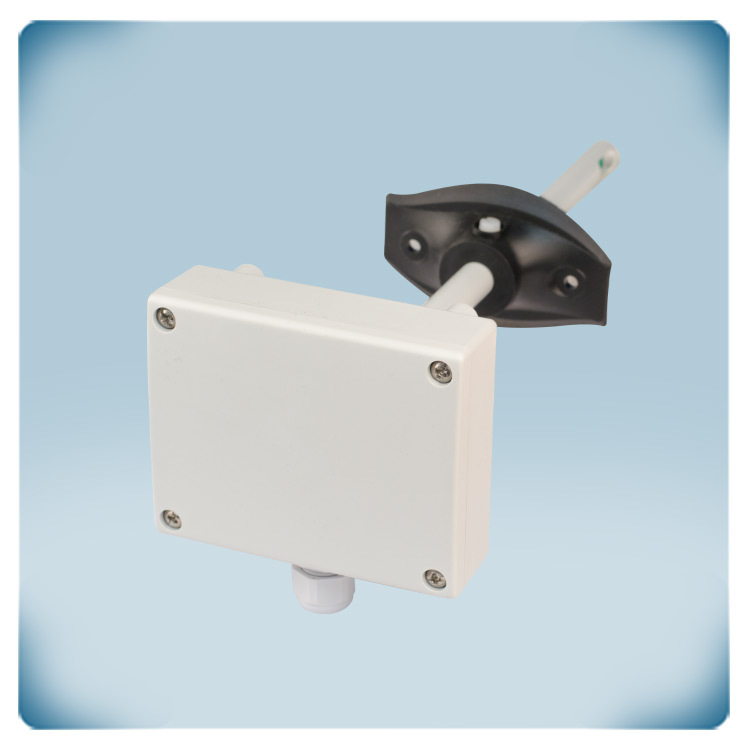

CO2 meter for air ducts. Next to CO2, it also measures temperature and relative humidity. Modbus RTU communication is used to transmit the measured values and to adjust the settings. This sensor has no analogue or digital outputs.

The supply voltage is 24 VDC. The pluggable screw terminal block simplifies connection.

NDIR technology is used to measure the CO2 concentration. To ensure long-term accuracy, this sensor is self-calibrating.

Documents

Additional specifications and description

What is the purpose of measuring CO2 in air ducts?

CO2 sensors are used as an indicator of ventilation requirements in many applications. When people breathe, they produce CO2 or carbon dioxide. As a result, CO2 concentration is a good predictor of a space's occupancy and activity level. By measuring the CO2 concentration in the extraction air duct, it can be determined whether there is sufficient ventilation. If the CO2 concentration becomes too high, an additional supply of fresh air is required to bring the CO2 concentration in the room back within the acceptable range.

Where should this sensor be installed?

The housing of this sensor is designed for mounting on an air duct. The sensor can be used on both circular and rectangular air ducts. To obtain a correct measurement, it is important that the sensor is not mounted in turbulent zones. Therefore we recommend installing this sensor in a straight section of the air duct. Avoid installing in turbulent air zones near filters, fans, cooling coils, and so on. The sensor element is built in near the opening in the probe. To ensure proper operation, the airflow must come into contact with the sensor element. That is why it is important to position the sensor probe correctly in relation to the airflow direction. More detailed information can be found in the mounting instructions.

How does this sensor measure CO2?

NDIR or Non-dispersive Infrared technology is used to measure the CO2 level. This technology has a low life-cycle cost and long-term precision and stability. This sensor also has a barometric air pressure measurement to increase the accuracy of the CO2 measurement and to compensate for height differences. More information about NDIR technology is available in our FAQ section.

NDIR or Non-dispersive Infrared technology is used to measure the CO2 level. This technology has a low life-cycle cost and long-term precision and stability. This sensor also has a barometric air pressure measurement to increase the accuracy of the CO2 measurement and to compensate for height differences. More information about NDIR technology is available in our FAQ section.

Does this CO2 sensor need to be recalibrated?

No, this sensor recalibrates itself. NDIR sensors can experience gradual drift in their baseline readings due to aging of components (like the IR source, detectors, or optical filters), contamination of optical paths, or changes in sensor electronics. Regular recalibration corrects for this drift to maintain accuracy. This sensor has an algorithm that performs these regular recalibrations. It is called 'ABC' or Automatic Baseline Correction. The ABC logic self-calibrating algorithm is by default enabled. This algorithm is designed to be used in applications where CO2 concentrations will drop to outside ambient conditions (±400 ppm) at least once in a 7day period (15 minutes or longer), which is typically seen during unoccupied periods. The lowest reading during a 7-day period is considered fresh outside air (the 'baseline). Immediately after first use, the sensor takes some time to reach its full accuracy. The sensor will reach its operational accuracy after 25 hours of continuous operation at a condition that it was exposed to ambient reference levels of air at 400 ppm ± 10 ppm CO2.

Also environmental influences like temperature, humidity, and pressure can affect NDIR sensor performance. In order to compensate for these influences, the sensor uses all measured values. This sensor will therefore perform a correct measurement, regardless of the height at which it is installed, because the NDIR measurement is corrected with the barometric pressure measurement.

What else does this sensor measure besides CO2?

This HVAC transmitter detects temperature, relative humidity, barometric pressure and CO2 levels in air ducts. The dew point is calculated based on the temperature and humidity. These are the most important parameters for controlling a ventilation system. Based on these measurements, a comfortable indoor climate can be created for the occupants. All these measurements can be read out via Modbus RTU communication (this sensor has no digital or analog outputs).

How should this sensor be connected?

This sensor requires a supply voltage of 24 VAC or 24 VDC. In addition, Modbus RTU communication is required to read out measured values and change settings. Modbus RTU communication and the supply voltage are connected via the pluggable screw terminal block. The pluggable terminal block simplifies installation: the cable can be connected at an easily accessible location and then the connector can be plugged into the sensor.

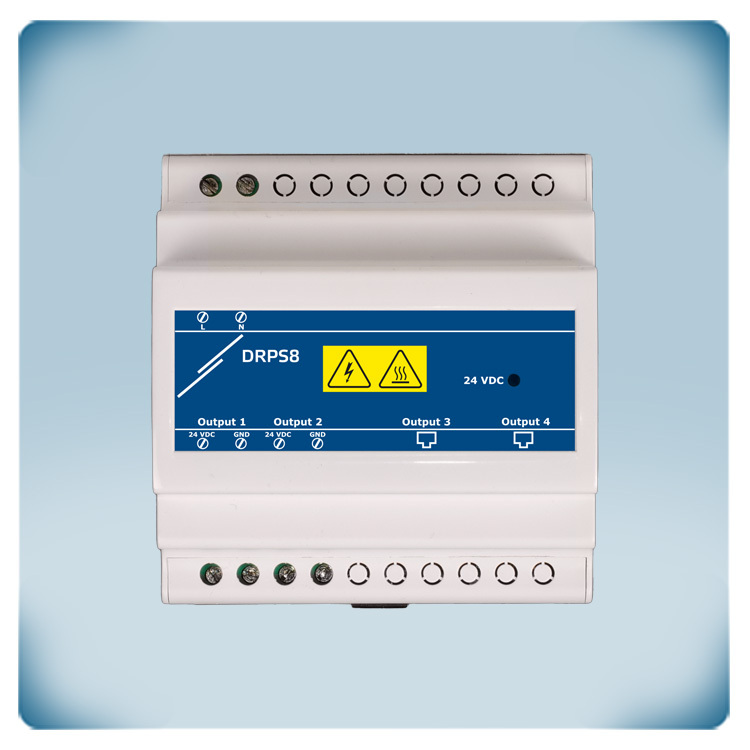

This sensor can be powered by either 24 VAC or 24 VDC. Sentera recommends using 24 VDC for powering sensors. Most 24 VDC power supplies provide short-circuit, overload, and overvoltage protection. A supply voltage of 24 VDC improves the safety and reliability of your installation.

How can the measurements of the sensor be read?

This sensor does not have analogue outputs which makes it simpler and more cost efficient. All measured values are available via the Modbus input registers of this sensor. Reading the measured values is possible via SenteraWeb - our online HVAC platform, via a BMS system or via another Modbus master device. Modbus RTU communication has numerous advantages. The most important ones are that digital signals are less susceptible to interference than analogue signals and that longer cables can be used. More information about Modbus RTU communication is available in our FAQ section.

How can I change the settings of this CO2 sensor?

This CO2 sensor has standard settings that are applicable for most ventilation applications in the residential sector. For most applications, no settings changes are required, allowing the sensor to be put into operation immediately after installation. If settings need to be changed, you can do this by changing the values of the Modbus holding registers. For this we recommend using SenteraWeb. How to adjust settings of Sentera devices is also explained in our FAQ section.

Is this duct sensor waterproof?

The enclosure is designed for CO2 measurements in air ducts. It fits both circular and rectangular air ducts. So typically, this sensor is installed indoors. The enclosure offers an IP54 protection against ingress of dust and moisture. The sensor element is integrated in the probe of the duct sensor. This probe has an opening to have a direct contact between the air flow and the sensor element. The sensor probe offers an IP20 protection. To minimize the effects of moisture and the risk of corrosion, the electronics are protected with a special coating.

.webp)

.webp)

.webp)

.webp)

.webp)

Remarks, reviews & ratings