EU declaration conformity

Frequency inverter | 10.5 A | 2.2 kW | IP20

Product description

Simple frequency drive for HVAC applications that can be used to regulate fans or centrifugal pumps with three-phase, 230 Volt motors. To control three-phase 230 Volt motors, the frequency drive needs a single-phase 230 Volt supply voltage. The frequency drive converts the single-phase 230 Volt supply into three-phase 230 Volt supply for the motor.

Motors with a maximum (combined) current of 10.5 A can be controlled by this drive. It is designed to control IE3, IE4, permanent magnet, brushless DC, or synchronous reluctance motors - all these motor types can be operated by this frequency inverter.

The user-friendly keypad or the inputs can be used to adjust the motor speed. By turning on a digital input, a predetermined motor speed can be chosen. Defining the motor speed with a 0–10 Volt signal is an additional choice. All of this can be configured more easily with the help of 14 fundamental parameters and application macro functions.

The enclosure can be DIN rail mounted in an electrical cabinet. It offers an IP20 protection against ingress of dust. The integrated EMC filter is Class C1.

Manufacturers code: ODE-3-220105-1F42

Documents

Additional specifications and description

Is it possible to have optimal motor control?

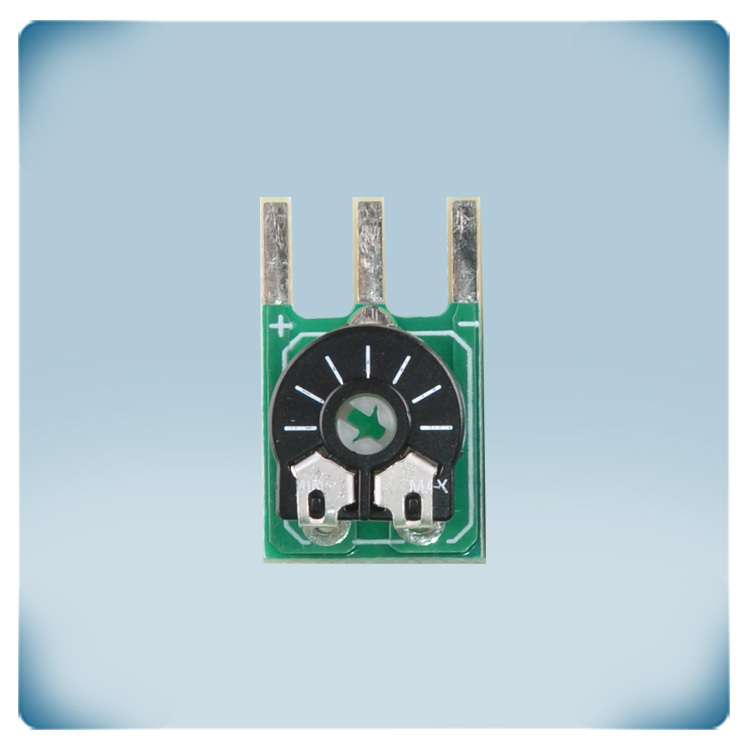

By default, input 1 is used to start the motor. An optional 10K potentiometer can be connected to terminals 5, 6 and 7 to adjust fan speed.

When input 3 is activated, the motor runs at the predefined speed in parameter 20. When input 3 is not activated (or not connected), the motor speed can be adjusted via the external potentiometer (or analogue control signal).

What is the technology behind the optimal motor control?

This frequency inverter requires a single-phase 230 V power supply. It controls standard 3-phase 230 V IE2, IE3 and IE4 induction motors. On top of that, it can also control Permanent Magnet motors, Brushless DC Motors and Synchronous Reluctance Motors.

Remarks, reviews & ratings