EU declaration conformity

Dual pressure transmitter with display 2000 Pa - 24 VAC or VDC supply

Product description

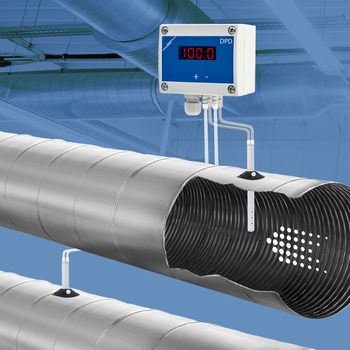

This sensor offers versatile functionality, capable of measuring either differential pressure or air volume flow using its two inputs. It can also provide air velocity readings when a Pitot tube set is connected.

Measured values are transmitted through two analog outputs, which can be configured for 0-10 VDC, 0-20 mA, or 0-100% PWM. You can also adjust and monitor all parameters remotely using Modbus RTU communication. For convenient, real-time visualization, it includes a 7-segment LED display.

The device operates on a 24 VAC or 24 VDC supply voltage and is commonly used for monitoring the volume flow of supplied and extracted air in ventilation systems or Air Handling Units (AHUs), with a pressure range of 0 to 2,000 Pa.

Documents

Additional specifications and description

What Can This Sensor Measure and Calculate?

The DPD pressure transmitter (or sensor) is capable of measuring the differential pressure in two different locations simultaneously. This functionality enables users to calculate either air volume flow or air velocity based on the measured data.

For calculating air volume flow based on the K-factor of the fan, users can utilize the PSET-PVC-200 or PSET-QF-200 connection set types. These connection sets provide the necessary components and parameters to accurately determine air volume flow based on the specific characteristics of the fan being used. Additionally, these connection sets can also be utilized for measuring differential pressure when required.

To calculate air volume flow based on the duct cross section or air velocity, users can employ the PSET-PTS-200 or PSET-PTL-200 connection sets. These facilitate the calculation of air volume flow or air velocity based on the dimensions of the duct cross section and the measured air velocity.

By selecting the appropriate connection set based on the specific requirements of the application, users can effectively utilize the DPD pressure transmitter to measure and calculate air volume flow or air velocity in HVAC systems with accuracy and precision.

How Are Measured Values Displayed and Transmitted?

The measured values are transmitted via the analogue outputs and via Modbus RTU communication. The two values are indicated alternately on the 7-segment LED display. The display can be disabled via Modbus RTU.

What Are the Analog Output Capabilities and Default Settings?

The DPD pressure transmitter is equipped with two analogue outputs, each capable of transmitting measured values of either differential pressure, air volume flow, or air velocity in a proportional manner.

By default, the sensor operates within a range of 0 to 2.000 Pa, with the analogue outputs configured to transmit 0 V at 0 Pa and 10 V at 2.000 Pa. This default setup ensures compatibility with standard measurement requirements. However, users have the flexibility to adjust various parameters, including the measurement range, output types and other settings, via Modbus RTU communication.

What Are the Key Applications and Connectivity Options?

The DPD pressure transmitter provides the capability to measure air volume flow in two distinct locations simultaneously, making it ideal for monitoring both supplied and extracted air volume in various systems such as ventilation systems or Heat Recovery Units (HRUs). This dual measurement functionality enables comprehensive monitoring and control of airflow within these systems, facilitating efficient operation and maintenance.

This sensor can be connected to internet via a Sentera internet gateway. This makes it possible to log data or to adjust settings remotely.

What Are the Power Supply and Wiring Requirements?

The screw clamp terminal block facilitates the connection of the supply voltage, both outputs, and Modbus RTU communication. This sensor can be powered either by 24 VDC or 24 VAC and is designed for a 3-wire connection setup. The ground of the output (GND) is internally connected to the ground of the supply voltage (V-). However, it is important to avoid connecting this common ground to other devices powered by a DC voltage.

What Are the Sensor's Physical and Durability Features?

The enclosure is made of high-quality r-ABS VO (UL94) plastic. This material is heat resistant, very tough and offers good protection against impacts. The pressure connection nozzles are made from aluminium. The sensor enclosure offers an IP65 protection against ingress of dirt and water. This sensor can be wall-mounted both indoors and outdoors.

The DPD pressure transmitter is equipped with two analogue outputs, each capable of transmitting measured values of either differential pressure, air volume flow, or air velocity in a proportional manner.

By default, the sensor operates within a range of 0 to 2.000 Pa, with the analogue outputs configured to transmit 0 V at 0 Pa and 10 V at 2.000 Pa. This default setup ensures compatibility with standard measurement requirements. However, users have the flexibility to adjust various parameters, including the measurement range, output types and other settings, via Modbus RTU communication.

What Are the Key Applications and Connectivity Options?

The DPD pressure transmitter provides the capability to measure air volume flow in two distinct locations simultaneously, making it ideal for monitoring both supplied and extracted air volume in various systems such as ventilation systems or Heat Recovery Units (HRUs). This dual measurement functionality enables comprehensive monitoring and control of airflow within these systems, facilitating efficient operation and maintenance.

This sensor can be connected to internet via a Sentera internet gateway. This makes it possible to log data or to adjust settings remotely.

What Are the Power Supply and Wiring Requirements?

The screw clamp terminal block facilitates the connection of the supply voltage, both outputs, and Modbus RTU communication. This sensor can be powered either by 24 VDC or 24 VAC and is designed for a 3-wire connection setup. The ground of the output (GND) is internally connected to the ground of the supply voltage (V-). However, it is important to avoid connecting this common ground to other devices powered by a DC voltage.

What Are the Sensor's Physical and Durability Features?

The enclosure is made of high-quality r-ABS VO (UL94) plastic. This material is heat resistant, very tough and offers good protection against impacts. The pressure connection nozzles are made from aluminium. The sensor enclosure offers an IP65 protection against ingress of dirt and water. This sensor can be wall-mounted both indoors and outdoors.

.webp)

.webp)

.webp)

Remarks, reviews & ratings