EU declaration conformity

Differential pressure transmitter | 0 - 10 kPa | 24 VAC-VDC

Product description

This sensor measures differential pressure within a range of 0 to 10,000 Pa. It can also be used to measure air volume flow or air velocity.

It operates on a flexible power supply of either 24 VAC or 24 VDC. The measured values are available through a single analog output and Modbus RTU communication. The analog output is selectable and can be set to 0-10 VDC, 0-20 mA, or 0-100% PWM.

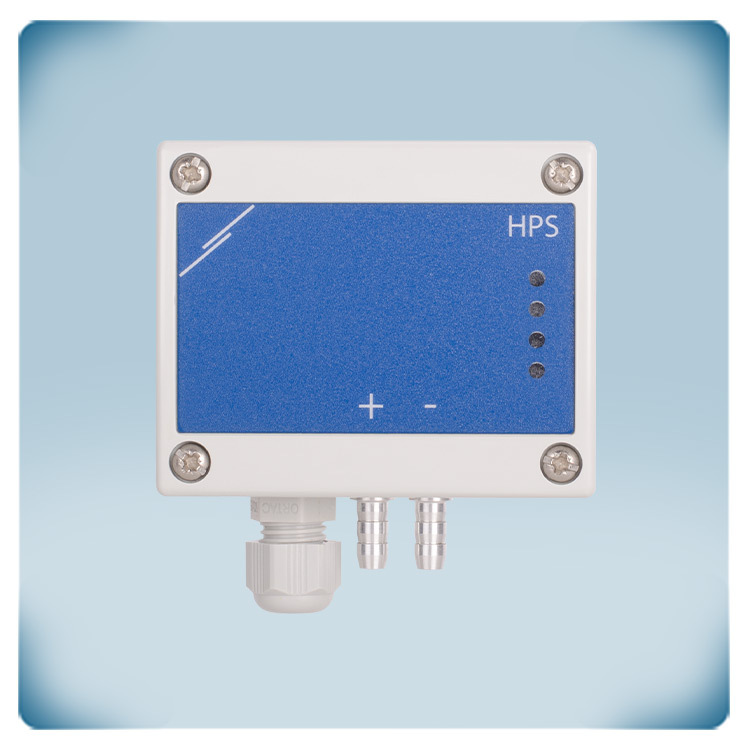

The device features four LED indicators for a visual display of the sensor status and measured values.

The differential pressure range and all other settings are fully adjustable via Modbus RTU.

Documents

Additional specifications and description

What Does the Sensor Measure and What Can It Calculate?

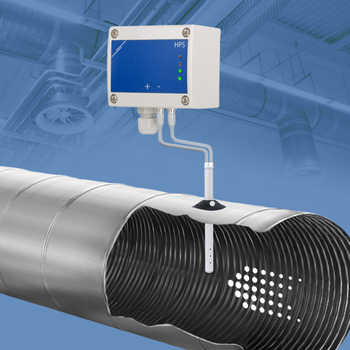

This sensor measures differential pressure [Pa]. Based on this measurement, air volume flow [m³/hr] or air velocity [m/s] can be calculated. To calculate air volume flow based on the K-factor of the fan, use the connection set type PSET-PVC-200 or PSET-QF-200. This connection set can also be used to measure differential pressure. To calculate air volume flow based on the duct cross section [cm²] or air velocity [m/s], use the connection set type PSET-PTS-200 or PSET-PTL-200.

This sensor measures differential pressure [Pa]. Based on this measurement, air volume flow [m³/hr] or air velocity [m/s] can be calculated. To calculate air volume flow based on the K-factor of the fan, use the connection set type PSET-PVC-200 or PSET-QF-200. This connection set can also be used to measure differential pressure. To calculate air volume flow based on the duct cross section [cm²] or air velocity [m/s], use the connection set type PSET-PTS-200 or PSET-PTL-200.

How Does the Sensor Provide Visual Status?

This pressure transmitter offers a clear, visual indication of the differential pressure level via the green, yellow and red LED. The green LED indicates that the pressure level is within range. When the pressure level enters the alert range, the yellow LED lights up. Red means: differential pressure out of range. The LEDs can also indicate the status of the air volume flow or air velocity. The second green LED indicates the sensor status. It is activated when power supply and Modbus RTU communication are enabled.

This pressure transmitter offers a clear, visual indication of the differential pressure level via the green, yellow and red LED. The green LED indicates that the pressure level is within range. When the pressure level enters the alert range, the yellow LED lights up. Red means: differential pressure out of range. The LEDs can also indicate the status of the air volume flow or air velocity. The second green LED indicates the sensor status. It is activated when power supply and Modbus RTU communication are enabled.

What Are the Sensor's Output Features and How Are They Configured?

This sensor has one analogue output. It transmits the measured differential pressure, air volume flow or air velocity proportionally. The default range of this sensor is 0 to 10.000 Pa. By default, the output transmits 0 V at 0 Pa and 10 V at 10.000 Pa. This range, the output type and all other settings can be adjusted via Modbus RTU. The output type can be adjusted via Modbus RTU: 0-10 VDC / 0-20 mA / 0-100 % PWM.

This sensor has one analogue output. It transmits the measured differential pressure, air volume flow or air velocity proportionally. The default range of this sensor is 0 to 10.000 Pa. By default, the output transmits 0 V at 0 Pa and 10 V at 10.000 Pa. This range, the output type and all other settings can be adjusted via Modbus RTU. The output type can be adjusted via Modbus RTU: 0-10 VDC / 0-20 mA / 0-100 % PWM.

What Are the Power Supply and Wiring Requirements?

The supply voltage, the analogue output and Modbus RTU communication can be connected via the cage clamp terminal block. They eliminate the need for routine maintenance and guarantee a reliable contact for solid or stranded wires. This sensor can be supplied with 24 VDC or with 24 VAC. It is intended for 3-wire connection. The ground of the output (GND) is internally connected to the ground of the supply voltage (V-). Make sure not to connect this common ground to other devices that are powered by a DC voltage.

The supply voltage, the analogue output and Modbus RTU communication can be connected via the cage clamp terminal block. They eliminate the need for routine maintenance and guarantee a reliable contact for solid or stranded wires. This sensor can be supplied with 24 VDC or with 24 VAC. It is intended for 3-wire connection. The ground of the output (GND) is internally connected to the ground of the supply voltage (V-). Make sure not to connect this common ground to other devices that are powered by a DC voltage.

What Are the Sensor's Quality and Durability Features?

The enclosure is made of high-quality r-ABS VO (UL94) plastic. This material is heat resistant, very tough and offers good protection against impacts. The pressure connection nozzles are made from Aluminum. The sensor enclosure offers an IP65 protection against ingress of dirt and water. This sensor can be wall-mounted.

The enclosure is made of high-quality r-ABS VO (UL94) plastic. This material is heat resistant, very tough and offers good protection against impacts. The pressure connection nozzles are made from Aluminum. The sensor enclosure offers an IP65 protection against ingress of dirt and water. This sensor can be wall-mounted.

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

Remarks, reviews & ratings