EU declaration conformity

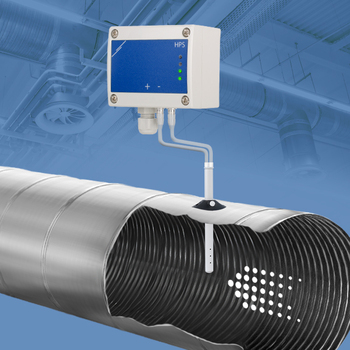

Differential pressure controller | -125 to 125 Pa | 24 VDC

Product description

Differential pressure controller for fans to generate a Variable Air Volume flow (VAV control). The supply voltage is 24 VDC.

The operating range is -125 to +125 Pa. It controls differential pressure or air volume flow. Air velocity control is also possible in combination with a Pitot tube connection set.

The analogue output can control EC fans, frequency inverters or AC fan speed controllers. The output type is selectable via Modbus RTU communication.

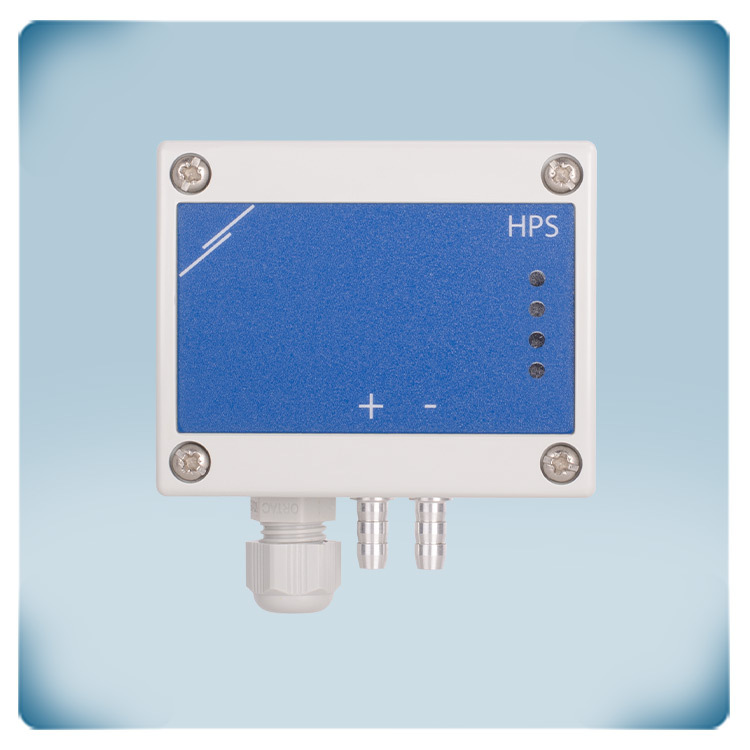

The four LED indicators provide a visual indication of the transmitter status and the controlled values. The differential pressure setpoint and all other settings can be adjusted via Modbus RTU.

Documents

Additional specifications and description

What are the Core Functions and Control Capabilities of the Pressure Controller?

This differential pressure controller controls EC fans or AC fan speed controllers. It maintains the differential pressure [Pa] constant at the set point. The operating range is -125 to +125 Pa. It is also possible to control fan speed based on air volume flow [m³/hr] or air velocity [m/s]. To control air volume flow based on the K-factor of the fan, use the optional connection set type PSET-PVC-200 or PSET-QF-200. This connection set can also be used to control differential pressure. To control air volume flow based on the duct cross section [cm²] or air velocity [m/s], use the optional connection set type PSET-PTS-200 or PSET-PTL-200. The setpoint can be adjusted via Modbus RTU.

This differential pressure controller controls EC fans or AC fan speed controllers. It maintains the differential pressure [Pa] constant at the set point. The operating range is -125 to +125 Pa. It is also possible to control fan speed based on air volume flow [m³/hr] or air velocity [m/s]. To control air volume flow based on the K-factor of the fan, use the optional connection set type PSET-PVC-200 or PSET-QF-200. This connection set can also be used to control differential pressure. To control air volume flow based on the duct cross section [cm²] or air velocity [m/s], use the optional connection set type PSET-PTS-200 or PSET-PTL-200. The setpoint can be adjusted via Modbus RTU.

What is PI Control and How is it Integrated?

PI stands for Proportional-Integral control, a type of feedback control system commonly used in engineering and control theory. This control system adjusts the output based on the difference between the desired setpoint and the actual value. Integrated PI control means that both proportional and integral actions are integrated into the control scheme.

How Does the Controller Provide Visual Feedback?

This pressure controller offers a clear, visual indication of the differential pressure level via the green, yellow and red LED. The green LED indicates that the pressure level is within range. When the pressure level enters the alert range, the yellow LED lights up. Red means: differential pressure out of range. The LEDs can also visualise the status of the air volume flow or air velocity. The second green LED indicates the sensor status. It is activated when power supply and Modbus RTU communication are enabled.

This pressure controller offers a clear, visual indication of the differential pressure level via the green, yellow and red LED. The green LED indicates that the pressure level is within range. When the pressure level enters the alert range, the yellow LED lights up. Red means: differential pressure out of range. The LEDs can also visualise the status of the air volume flow or air velocity. The second green LED indicates the sensor status. It is activated when power supply and Modbus RTU communication are enabled.

What are the Analog Output and Fan Control Features?

This pressure controller has one analogue output. This output controls EC fans or AC fan speed controllers based on the measured differential pressure, air volume flow or air velocity. The fan speed is controlled to maintain the measured value constant at the setpoint. The setpoint can be adjusted via Modbus RTU. To make this controller compatible with most EC fans and AC fan speed controllers, the output type can be adjusted via Modbus RTU: 0-10 VDC / 0-20 mA / 0-100 % PWM. To match the reaction time of the fan to the application, P and I factors can be adjusted via Modbus RTU.

This pressure controller has one analogue output. This output controls EC fans or AC fan speed controllers based on the measured differential pressure, air volume flow or air velocity. The fan speed is controlled to maintain the measured value constant at the setpoint. The setpoint can be adjusted via Modbus RTU. To make this controller compatible with most EC fans and AC fan speed controllers, the output type can be adjusted via Modbus RTU: 0-10 VDC / 0-20 mA / 0-100 % PWM. To match the reaction time of the fan to the application, P and I factors can be adjusted via Modbus RTU.

What are the Power Supply and Wiring Specifications?

The supply voltage, the analogue output and Modbus RTU communication can be connected via the cage clamp terminal block. They eliminate the need for routine maintenance and guarantee a reliable contact for solid or stranded wires. The supply voltage is 24 VDC. The ground terminals of the power supply (V-) and output (GND) are galvanically separated. This means that a 4-wire cable is required to connect this sensor. Most 24 VDC power supplies offer protection against short circuit, overload and overvoltage. A 24 VDC supply voltage increases the safety and reliability of your installation.

The supply voltage, the analogue output and Modbus RTU communication can be connected via the cage clamp terminal block. They eliminate the need for routine maintenance and guarantee a reliable contact for solid or stranded wires. The supply voltage is 24 VDC. The ground terminals of the power supply (V-) and output (GND) are galvanically separated. This means that a 4-wire cable is required to connect this sensor. Most 24 VDC power supplies offer protection against short circuit, overload and overvoltage. A 24 VDC supply voltage increases the safety and reliability of your installation.

What are the Physical and Durability Features of the Enclosure?

The enclosure is made of high-quality r-ABS VO (UL94) plastic. This material is heat resistant, very tough and offers good protection against impacts. The pressure connection nozzles are made from aluminium. The sensor enclosure offers an IP65 protection against ingress of dirt and water. This pressure controller can be wall-mounted.

The enclosure is made of high-quality r-ABS VO (UL94) plastic. This material is heat resistant, very tough and offers good protection against impacts. The pressure connection nozzles are made from aluminium. The sensor enclosure offers an IP65 protection against ingress of dirt and water. This pressure controller can be wall-mounted.

What are the Key Applications of this Low-Pressure Differential Pressure Controller?

A low-pressure differential pressure controller has various application fields across different industries and systems where precise control of airflow, fluid flow or pressure is essential.

A low-pressure differential pressure controller has various application fields across different industries and systems where precise control of airflow, fluid flow or pressure is essential.

In HVAC systems, low-pressure differential pressure controllers are used to regulate airflow in ductwork, ensuring proper ventilation and air distribution throughout a building. They help maintain desired air pressure differentials between different zones or rooms.

In cleanroom facilities, maintaining precise air pressure differentials is crucial for controlling contamination and ensuring product quality. Low-pressure differential pressure controllers play a vital role in achieving and maintaining these controlled environments.

Laboratories often require controlled airflow to maintain specific environmental conditions, such as temperature, humidity and cleanliness. Low-pressure differential pressure controllers are used in fume hoods, biosafety cabinets, and other containment systems to regulate airflow and protect researchers from exposure to hazardous materials.

In healthcare settings, low-pressure differential pressure controllers are used in isolation rooms, operating rooms and cleanrooms to control air quality and prevent the spread of infectious diseases.

.webp)

.webp)

.webp)

.webp)

.webp)

Remarks, reviews & ratings