EU declaration conformity

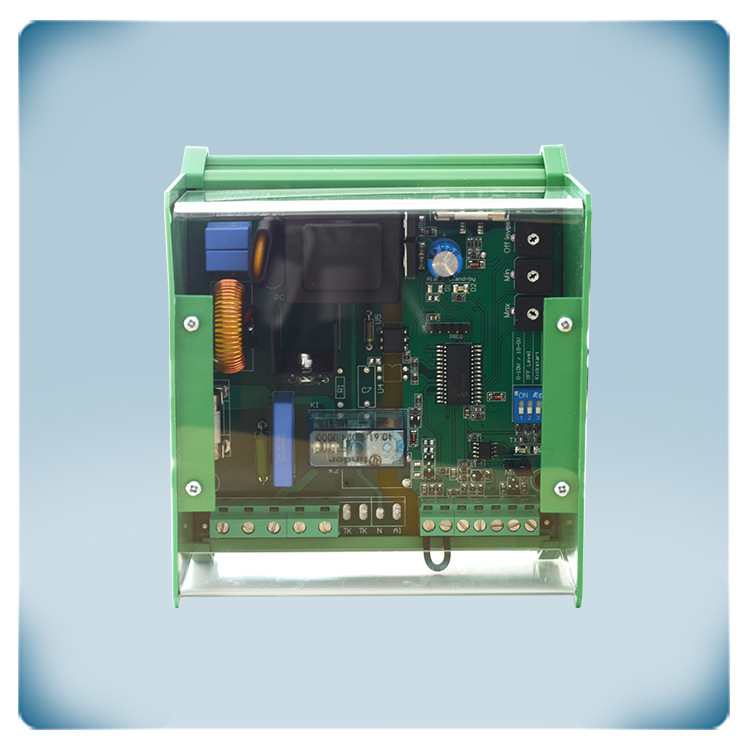

AC fan speed controller 0-10 V | DIN rail | 3 A

Product description

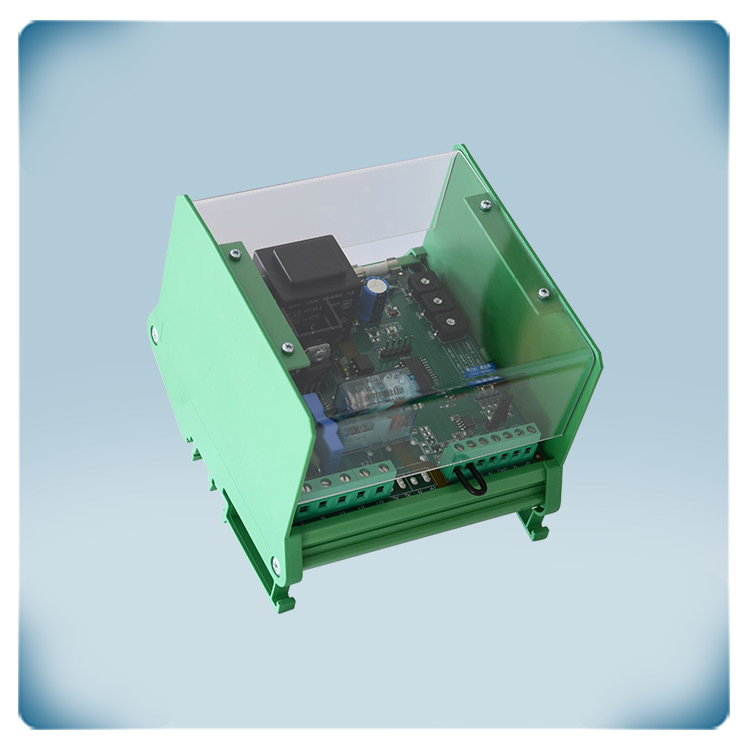

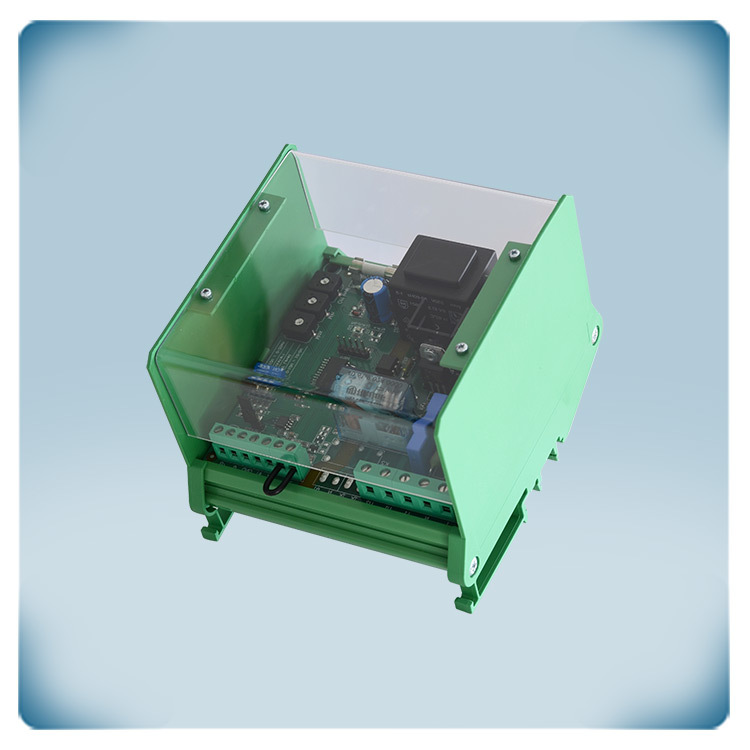

MVS is an electronic fan speed controller designed for single-phase, voltage-controlled motors with a maximum current of 3 A. It regulates fan speed by changing the motor voltage using phase-angle control with Triac technology. The controller has a housing for DIN rail mounting.

The motor voltage can be controlled via an analogue input or through Modbus RTU. The type of analogue input is selectable via a DIP switch, allowing for either 0-10 VDC or 0-20 mA signals. A remote start/stop command can be generated via the digital input.

The minimum and maximum speeds are adjustable via internal trimmers. The device also offers various operating modes, as well as Kick start or Soft start acceleration, all selectable via Modbus RTU. The unregulated output is activated when the motor is running.

Documents

Additional specifications and description

The requested fan speed can be set via the analogue input signal. This analogue signal can be 0-10V or 0-20 mA. This analogue input can be set in ascending or descending mode. In ascending mode, the motor will run at low speed when the analogue signal is at its minimum value (0 V). The motor will run at high speed when the analogue input is maximum (10 V). In descending mode, the operation is inversed.

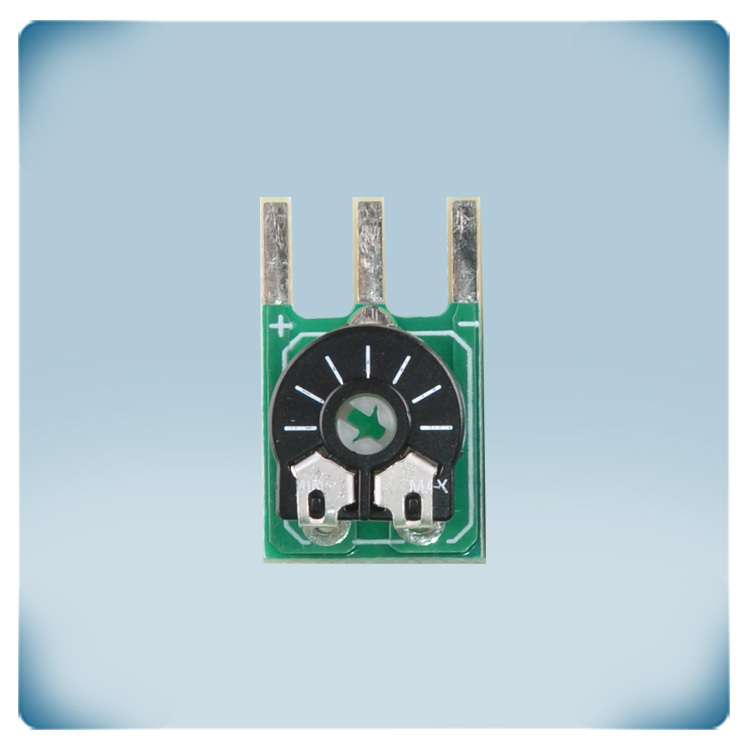

In case there is no 0-10V signal available, you can connect an external 10 KOhm potentiometer via the integrated 12 VDC power supply.

The motor can be enabled or disabled via an external switch. This optional switch can be connect to the digital input of the fan speed controller.

For most applications, this variable speed controller can be used with the default settings. If necessary, the settings can be customised via Modbus RTU or via the dip switches and internal trimmers.

The enclosure can be DIN rail mounted and offers an IP20 protection against ingress of dirt, dust and moisture. The plastic cover offers protection against contact with live parts.

The unregulated output (230 VAC) is active when the motor is enabled. It can be used to control an external run-indicator, a damper, etc.

E.g. when the fan is deactivated, the damper is closed. When the fan is active, the damper is open.

.webp)

.webp)

.webp)

Remarks, reviews & ratings