EU declaration conformity

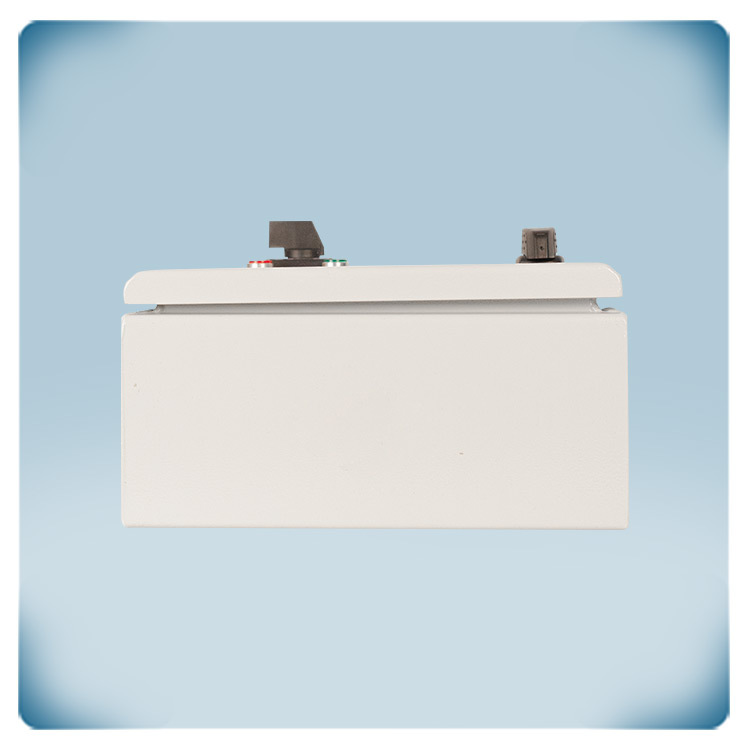

Fan speed controller 400 V | gas valve control | 2,5 A

Product description

This is a 5-step fan speed controller for 400V AC fans with a maximum current of 2.5 A, making it perfect for kitchen hood exhaust systems. It has a built-in rotary switch for manual speed adjustment and an integrated relay for controlling an external gas valve.

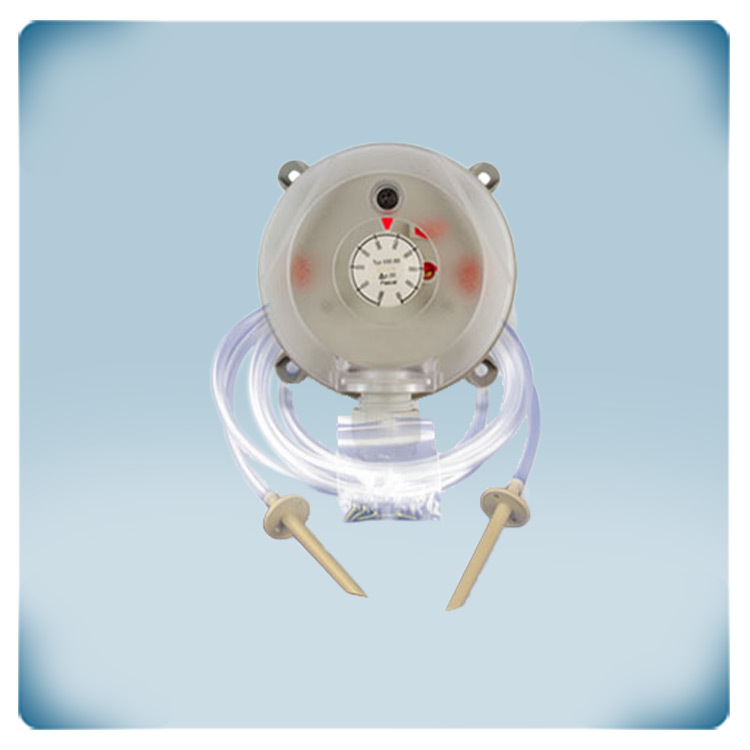

The controller includes an optional pressure relay that shuts off gas flow if no airflow is detected within 60 seconds of motor startup, ensuring it meets local safety rules. A thermal contact (TK) monitoring feature automatically deactivates the motor in case of overheating. The motor can be started with the rotary switch or remotely, and it restarts automatically after a power failure.

The unit is designed for surface mounting and has an IP54-protected enclosure, making it suitable for indoor use by providing protection against dirt and moisture.

Documents

Additional specifications and description

How Does the Transformer Controller Regulate Three-Phase AC Motor Speed?

The device has a protection level of IP54 and is only suitable for surface mounting.

How Does the Relay Output Control External Gas Supply and Ensure Safety?

The relay output is intended for controlling an external gas valve. The gas supply is only switched on when the exhaust fan is active. If no airflow is detected within 60 seconds, the gas valve will close. A pressure relay or switch must be connected to the FL input. This is not included in the scope of delivery. For this purpose, the PSW differential pressure switch can be used.

What Remote Control Capabilities Does the SFPR4 Offer?

The SFPR4 is equipped with a contact that can be used to turn the controller on and off via a remote switch or thermostat.

How Does the SFPR4's TK Monitoring System Protect Motors from Overheating?

This 5-step transformer controller can monitor thermal motor contacts (TK or thermal contacts measure the temperature in the motor windings). In the event of motor overheating, the TK monitoring function shuts down the motor to prevent damage. If the motor is not equipped with TK contacts, bridge the TK terminals of the SFPR4 transformer controller to simulate normal motor temperature.

What is the Function of the SFPR4's Normally Closed Contact for Motor Activation?

The SFPR4 transformer controller has a normally closed contact. This allows the motor to be activated or deactivated remotely.

What is the Purpose and Use of the SFPR4's Unregulated Output?

The unregulated output (230 VAC) is active when the motor is activated. It can be used to control an external operating indicator light, a damper, etc. For instance, the lighting of the extractor hood can be activated at the same time as the fan.

How Does the Device Behave During and After a Power Interruption?

If power is interrupted, the device will automatically restart when power is restored.

What are the Installation and Enclosure Features of the SFPR4 Controller?

Make sure that the speed controller can cool sufficiently. It is preferable to install it in a cool place, preferably not in direct sunlight. The housing is made of high quality steel. This material is very robust and offers good protection against impacts. It is RAL-7032 powder coated. The case is very strong and perfectly protects against shocks. It is suitable for surface mounting and meets IP54 protection class, protects against dust and moisture.

How Does the Relay Output Ensure Gas Supply Safety with Airflow Detection?

A relay output can control an external gas supply valve. The gas supply will only be turned on when the exhaust fan is turned on. If no airflow is detected within 60 seconds, the gas flow will be stopped.

What Additional Control Options Does the Unregulated Output Provide?

The controller has an additional non-regulated 230 VAC output to which an actuator or water valve can be connected to open the water supply to the water heater, this output is activated when any speed of the controller is activated

What Alarm and Remote Control Features Does the Regulator Offer?

The regulator also has an alarm output to which a 230 V fault indicator light can be connected, which will turn on when the motor thermal protection is activated, the controller also has COM, NO, NC contacts that can be used for remote stopping of the controller or connecting any other device.

What are the Environmental Operating Conditions and Protection Class of the Controller?

Since the enclosure of the controller complies with the IP54 ingress protection class, which allows it to work in moderately harsh conditions, its operating temperature can vary from -20 - 35 °C, and humidity is allowed 5 - 95% rH, no condensation is permissible.

.webp)

.webp)

.webp)

.webp)

.webp)

Remarks, reviews & ratings