EU declaration conformity

Configurator for Sentera products

Product description

SENSISTANT is a tool developed for configuring Sentera devices that feature Modbus RTU communication. It provides a convenient way to configure products without the need for a computer. The tool itself features a 4,3-inch TFT touch screen with intuitive interface.

SENSISTANT establishes communication with the connected Sentera device through Modbus RTU protocol enabling seamless data exchange and configuration between the tool and the device, ensuring efficient setup and customization.

To power the SENSISTANT tool and the connected Sentera product, it requires Power over Modbus (PoM) supply. This means that both the Modbus RTU communication and the 24 VDC supply voltage can be conveniently connected using one UTP cable crimped with an RJ45 connector.

The PoM capability simplifies the power supply setup, enhancing the convenience of the configuration process.

Documents

Additional specifications and description

SENSISTANT provides easy adjustment and reading of the device parameters, it is compact, extremely easy to use and durable. Its resistive touch screen is highly durable, it can withstand scratches, impacts, and harsh environmental conditions, making them suitable for industrial applications. It can register touch inputs even when the user is wearing gloves, which is particularly useful in cold weather or industrial settings where workers wear protective gear. What is more, resistive touch screens typically consume less power compared to capacitive touchscreens.

How to connect?

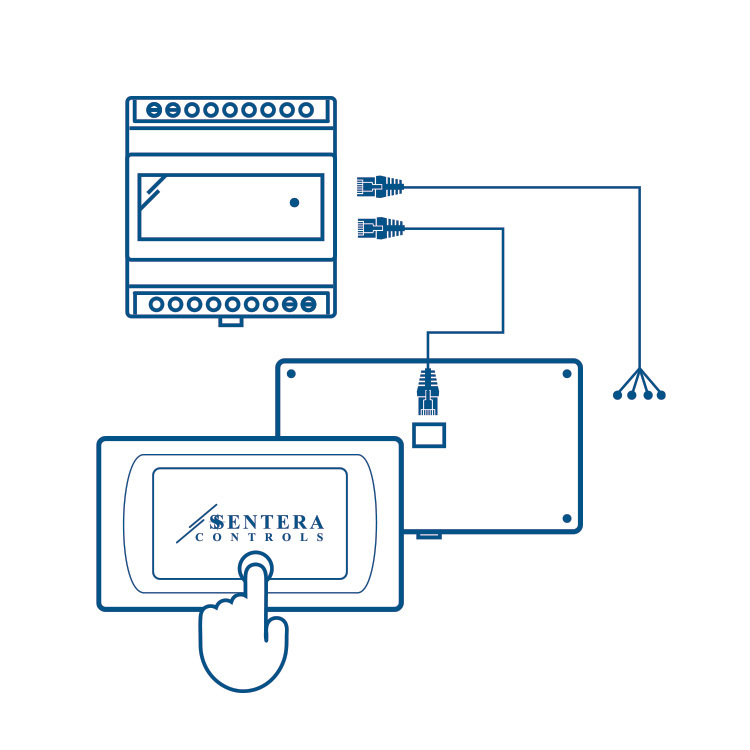

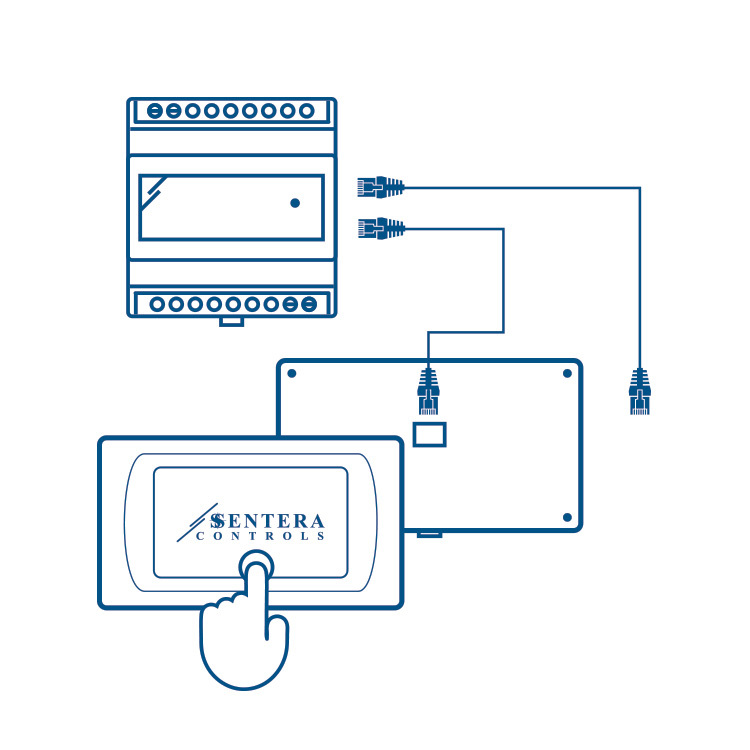

The SENSISTANT is supplied Power over Modbus (PoM). It is a feature that allows devices to receive power through the Modbus communication network itself, eliminating the need for separate power wiring. This feature combines both power and data transmission over the same communication bus, simplifying installation and reducing the overall wiring complexity.

In a PoM setup, the power is supplied to the devices through the same cable that is used for Modbus communication. The power is provided using a voltage source, namely 24 VDC power supply module with built-in Modbus repeater. SENSISTANT can be connected to the supply module via a UTP cable with RJ45 connectors at both ends. The other Sentera device can be connected via the terminal blocks or via the other RJ45 connector.

How it operates?

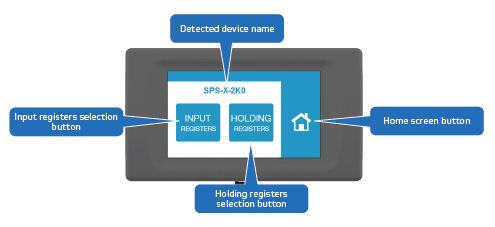

When connected to the power supply, SENSISTANT loads the start screen. By pressing the SCAN button, the search for connected devices is initiated. Having recognized the connected sensor / controller, the name of the detected device and the Modbus Input and Holding Registers are displayed. The holding registers can be modified, while the input registers are read-only.

Input registers are designed to hold data that can only be read by a Modbus master. This data is often provided by sensors, meters, or other devices that do not require external control. Modbus input registers play a crucial role in monitoring and collecting data from various sensors and measurement devices in industrial settings.

Modbus holding registers are another type of data storage location used in the Modbus communication protocol, which is commonly used in industrial automation and control systems. Holding registers are distinct from input registers in that they store data values that can be both read and written. They are used in settings where control and configuration of devices or processes are required. Each holding register is identified by a unique address within the Modbus network. Holding registers are crucial for configuring and controlling various devices, such as motor controllers, programmable logic controllers (PLCs), and other equipment in industrial settings. They allow for dynamic and real-time communication between master and slave devices, making them a key component of Modbus communication in process control and automation systems.

.webp)

.webp)

.webp)

.webp)

.webp)

Remarks, reviews & ratings