Switch disconnectors and motor circuit breakers

A switch disconnector, also known as an isolator switch, is intended for isolating power from electrical equipment connected to a circuit. This is primarily done to ensure safety and security, especially during maintenance and repair activities. Also, disconnectors break electrical circuits to halt the flow of current therefore they are extensively utilized in various industrial and factory applications. During operations, disconnectors are paired with switches, linked with earthing wires to provide additional safety to professionals dealing with intricate electrical issues or conducting maintenance and repair tasks in work areas. However, disconnectors do not control circuits; their sole function is to safely isolate power flow.

The EME5 series of switch disconnectors find applications in various industries and settings. These devices are known for their ease of installation and commissioning, high levels of safety and reliability, low maintenance requirements due to robust design and the option to be locked, thus eliminating the possibility of accidental switching on.

Isolation of components from energized sections of the system is the simplest (no-load) switching operation. Isolation is usually necessary for safe maintenance, repair and replacement of power system components. Only after isolation, can a person approach the relevant equipment. Frequently it could be a legal requirement to have a visible break between live and workable parts.

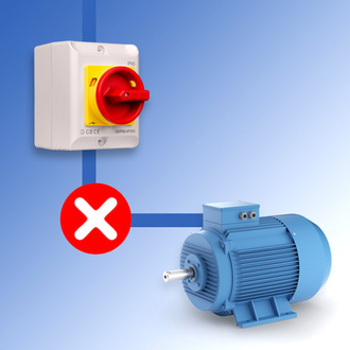

Isolator switches disconnect motors and electrical equipment.

Load isolation (on/off) switches or disconnectors are distribution equipment widely employed in factories, commercial, and industrial settings for breaking circuits, manual switching and isolating mains supply.

Often referred to as power isolators, switch disconnectors are used to disconnect electrical equipment for repair and maintenance purposes or in the event of an emergency. Especially when comes to handling highly-powered electrical equipment, it is imperative to fully discharge the electricity before initiating any repair or maintenance activities. Beyond simply cutting off the electrical flow, the disconnector also aids in the separation of various components within the electrical system.

The operating principle of a switch disconnector is straightforward. It disconnects the current or power source, facilitating easy and safe execution of maintenance, inspection and repair tasks by electricians, mechanics or technicians. These switches ensure the safety of both equipment and personnel. By minimizing the risks associated with mechanical and electrical accidents, they contribute to the establishment of a secure working environment. This is especially crucial during periods of repair and maintenance activities. To ensure safe maintenance at all times, the EME5 switches can be mechanically locked in the OFF position with a padlock.

The operating principle of a switch disconnector is straightforward. It disconnects the current or power source, facilitating easy and safe execution of maintenance, inspection and repair tasks by electricians, mechanics or technicians. These switches ensure the safety of both equipment and personnel. By minimizing the risks associated with mechanical and electrical accidents, they contribute to the establishment of a secure working environment. This is especially crucial during periods of repair and maintenance activities. To ensure safe maintenance at all times, the EME5 switches can be mechanically locked in the OFF position with a padlock.Nevertheless, the primary purpose of on/off switches is to function as emergency off-devices. Consequently, they must be readily identifiable, easily accessible and constantly visible to operators. This is why isolator switches feature special colours to meet the requirements of relevant electrical standards and codes.

What we have in our homes is a simple switch or handle and a plug to connect an electric device to the power supply. When we push the button, press the handle or unplug the cable, the device is de-energised. Unlike residential setups where disconnecting a plug turns off electricity, industrial machines and equipment are interconnected. In many cases, one unit may need to be disconnected for repair while others continue to function normally. Consequently, a straightforward pull of the plug is not sufficient in such industrial scenarios. That’s where disconnectors come in handy. They disconnect the electricity from the appliance. Cutting the power supply ensures the workers safety and prevents possible risks of electrical shocks.

How does it work?

How does it work?The main function of an isolator switch is to disconnect the electrical power from the load (e.g. motor). The switch contains two metal plates, which separate on the opening of the switch. By turning the rotary knob, the metal plates can be separated (OFF position) or closed (ON position). When the metal plates are separated, no more electrical current can flow.

A motor is an inductive load. When an inductive load is suddenly disconnected from the power supply, the electricity will try very hard to keep flowing. This is a well-known phenomenon — everyone has seen the sparking in a light switch when the lights are turned off. However, this spark formation also entails the risk that the metal plates of a switch will become welded together by the strong current that suddenly flows through them. If the contacts are welded shut due to an overcurrent, it is no longer possible to open the switch and interrupt the electrical current. This risk exists with a normal switch, but not with the EME5 switches! EME5 switches are equipped with forced opening safety contacts. Even if these contacts are welded shut due to an overcurrent, they are mechanically broken apart (forced open) by the ingenious mechanism. For this reason, the EME5 switches can also be used as emergency stop switches.

How can I select the correct switch for my project?

An electrical system with a single phase 230-volt supply can be disconnected from the mains by a two-pole disconnector switch. In these installations, L and N must be interrupted.

However, with 3-phase systems, 4 cables need to be interrupted: L1, L2, L3 and N. That is why disconnector switches for 3-phase systems have 4 poles.

However, with 3-phase systems, 4 cables need to be interrupted: L1, L2, L3 and N. That is why disconnector switches for 3-phase systems have 4 poles.

In some cases, feedback is also required as to whether the switch is active or not. This feedback can be provided via the auxiliary contact. This auxiliary contact can also be used for other purposes, such as closing a valve.

The EME5 range of switches includes models with 2 or 4 poles and auxiliary contacts. It's also important to check whether the switch can interrupt the maximum current. If in doubt, it's best to select a more robust type.

Switch disconnectors for 1-phase loads have 2 poles.

We offer a basic version without auxiliary contact for loads up to 2.2 kW and a version for loads up to 3.0 kW that features 1x NO and 1x NC auxiliary contacts.

Switch disconnectors for 3-phase loads have 4 poles.

The basic version can switch loads up to 3.7 kW and has no auxiliary contacts. The other 4-pole isolating switches loads up to 5.5, 15 or 30 kW. They feature 1x NO and 1x NC auxiliary contacts.