EU declaration conformity

Kitchen hood exhaust fan speed controller | 3,5 A

Product description

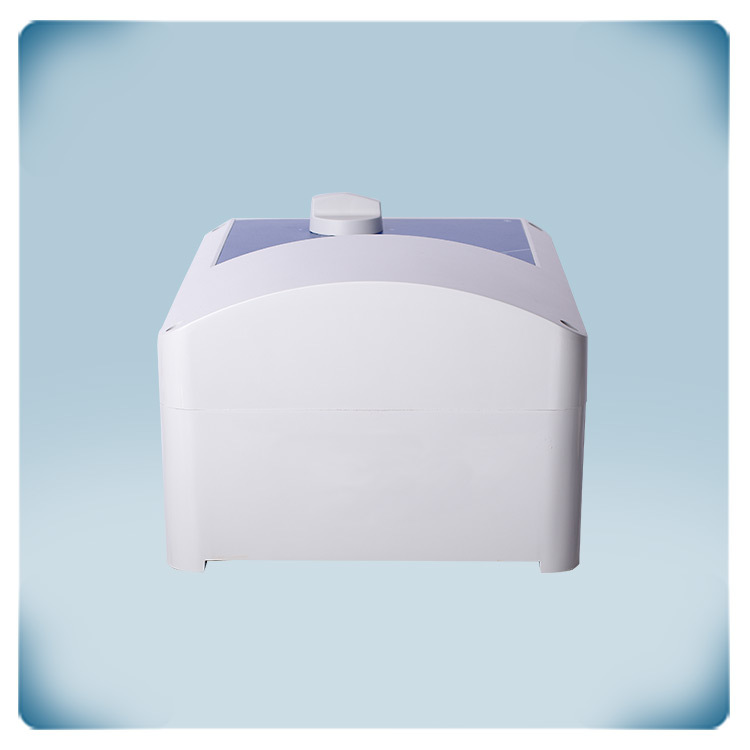

This is a single-phase AC fan speed controller designed specifically for kitchen hood exhaust systems. It features a built-in 5-step rotary switch for manual fan speed adjustment and can handle a maximum motor current of 3.5 A.

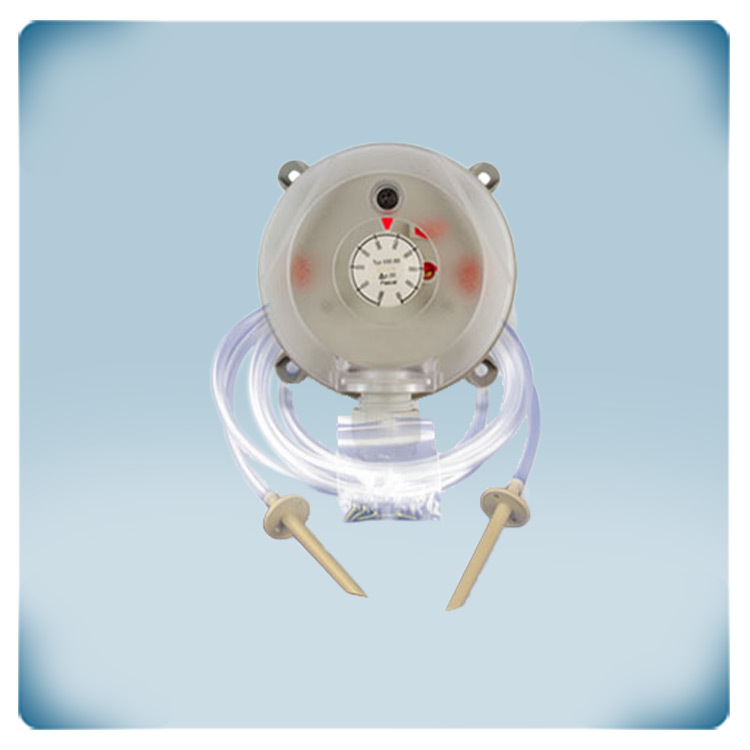

A key safety feature is the integrated relay for external gas valve control. If an optional pressure relay detects no airflow within 60 seconds of motor startup, the relay output will shut off the gas supply. It also includes TK monitoring to automatically deactivate the motor in case of a malfunction.

The controller is excellent for industrial kitchen hoods.

Its IP54-rated enclosure protects against dust and moisture and is designed for surface mounting.

Documents

Additional specifications and description

How Does the SFPR1's Autotransformer Technology Ensure Efficient and Quiet Fan Operation?

The operation of the SFPR1 is based on the use of a built-in autotransformer. It is used to control the voltage applied to the electric motor in five steps, which allows the fan speed to be varied. This technology is very reliable and durable. Sentera’s autotransformers also have a special impregnation to reduce the amount of electrical noise generated. The output voltage generated by the regulator is with a pure sine wave, which ensures quiet operation of the electric motor and increases its service life.

The operation of the SFPR1 is based on the use of a built-in autotransformer. It is used to control the voltage applied to the electric motor in five steps, which allows the fan speed to be varied. This technology is very reliable and durable. Sentera’s autotransformers also have a special impregnation to reduce the amount of electrical noise generated. The output voltage generated by the regulator is with a pure sine wave, which ensures quiet operation of the electric motor and increases its service life.

How Does the SFPR1's Gas Valve Output Enhance Safety in Industrial Kitchens?

The SFPR1 series of controllers feature a gas valve output, which opens only when the fan is working properly. When the controller is switched on, the gas valve actuator remains de-energized for one minute. If there is no air flow or pressure difference due to the operation of the fan during this period, the gas supply does not start. This operating logic makes the SFPR1 ideal for industrial kitchens.

What Remote Control and Monitoring Capabilities Does the SFPR1 Offer?

The SFPR1 transformer fan speed controller additionally has a normally closed contact. It can be used to remotely turn the controller on and off, as well as to monitor its operation. Thermostats, temperature relays, etc. are used.

What is the SFPR1's Behavior in Case of a Power Failure?

When working with electrical equipment, you should always be aware of possible power failures. In the event of such a failure, after the power is restored, the speed controller and motor will restart automatically.

How Does the SFPR1's Thermal Motor Protection System Function?

The SFPR1 fan speed controller is equipped with terminals for connecting the thermal motor protection contacts (TK). Thermal contacts are used to measure the temperature on the motor windings. In the event of overheating, the motor will be stopped to eliminate the risk of damage or failure. After the overheating protection trips, the speed controller is restarted manually. If the motor is not equipped with thermal contacts, the TK terminals must be connected together (via a bridge) to simulate its normal operation.

What is the Purpose and Use of the SFPR1's Unregulated Output?

The SFPR1 speed controller has an additional unregulated output (230 V) that is active when the motor is running. It is called unregulated because it has only two positions - on (230 V) and off (0 V). The maximum current for this output must not exceed 2 A. One example of the use of this output is to control a gas valve motor. In the absence of a separate power supply, the gas valve motor is connected to an unregulated output. If it is necessary to remotely control the operation of the transformer regulator, a lamp can be connected to the unregulated output.

What Do the LED Indicators on the SFPR1 Controller Signify?

The SFPR1 fan speed controller is equipped with LED indicators located on the unit housing. When power is connected to the transformer controller, the indicator will turn green. The red indicator lights up in one of the following cases: motor protection against overheating, lack of air flow or pressure difference, decrease in air flow or pressure difference during operation.

What are the Material, Protection, and Installation Features of the SFPR1 Enclosure?

The main purpose of the housing is to protect the internal part of the controller from the ingress of external contaminants and moisture, as well as from adverse environmental factors. The enclosures of our products are produced in-house in order to guarantee their quality and long life. They are made from r-ABS (reinforced Acrylonitrile Butadiene Styrene) with a VO flame-retardant rating. This material is fire-resistant and the enclosure is designed for surface installation. The material is reinforced for enhanced mechanical properties, improved fire safety, and reduced flammability. The protection class of the enclosure is IP54, indicating resistance to dust and water ingress.

What Remote Control and Monitoring Capabilities Does the SFPR1 Offer?

The SFPR1 transformer fan speed controller additionally has a normally closed contact. It can be used to remotely turn the controller on and off, as well as to monitor its operation. Thermostats, temperature relays, etc. are used.

What is the SFPR1's Behavior in Case of a Power Failure?

When working with electrical equipment, you should always be aware of possible power failures. In the event of such a failure, after the power is restored, the speed controller and motor will restart automatically.

How Does the SFPR1's Thermal Motor Protection System Function?

The SFPR1 fan speed controller is equipped with terminals for connecting the thermal motor protection contacts (TK). Thermal contacts are used to measure the temperature on the motor windings. In the event of overheating, the motor will be stopped to eliminate the risk of damage or failure. After the overheating protection trips, the speed controller is restarted manually. If the motor is not equipped with thermal contacts, the TK terminals must be connected together (via a bridge) to simulate its normal operation.

What is the Purpose and Use of the SFPR1's Unregulated Output?

The SFPR1 speed controller has an additional unregulated output (230 V) that is active when the motor is running. It is called unregulated because it has only two positions - on (230 V) and off (0 V). The maximum current for this output must not exceed 2 A. One example of the use of this output is to control a gas valve motor. In the absence of a separate power supply, the gas valve motor is connected to an unregulated output. If it is necessary to remotely control the operation of the transformer regulator, a lamp can be connected to the unregulated output.

What Do the LED Indicators on the SFPR1 Controller Signify?

The SFPR1 fan speed controller is equipped with LED indicators located on the unit housing. When power is connected to the transformer controller, the indicator will turn green. The red indicator lights up in one of the following cases: motor protection against overheating, lack of air flow or pressure difference, decrease in air flow or pressure difference during operation.

What are the Material, Protection, and Installation Features of the SFPR1 Enclosure?

The main purpose of the housing is to protect the internal part of the controller from the ingress of external contaminants and moisture, as well as from adverse environmental factors. The enclosures of our products are produced in-house in order to guarantee their quality and long life. They are made from r-ABS (reinforced Acrylonitrile Butadiene Styrene) with a VO flame-retardant rating. This material is fire-resistant and the enclosure is designed for surface installation. The material is reinforced for enhanced mechanical properties, improved fire safety, and reduced flammability. The protection class of the enclosure is IP54, indicating resistance to dust and water ingress.

.webp)

.webp)

.webp)

.webp)

.webp)

Remarks, reviews & ratings