EU declaration conformity

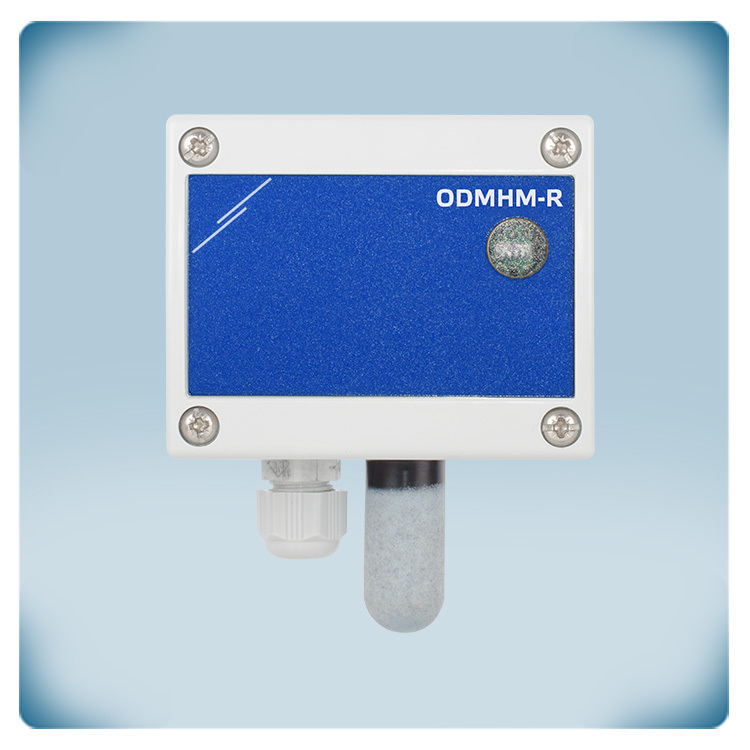

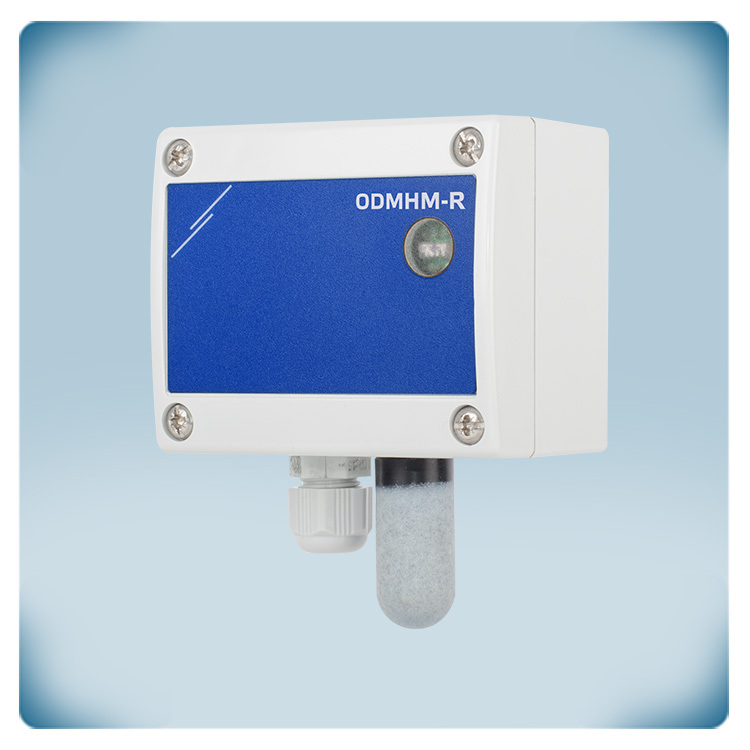

CO2 sensor | Humidity protection | IP65 enclosure | PoM

Product description

Measurement & Control: It measures temperature, humidity, CO2, and ambient light with selectable ranges. Its ambient light sensor (with adjustable active/standby levels) provides day/night detection for ventilation control. The CO2 sensor element is replaceable for easy maintenance.

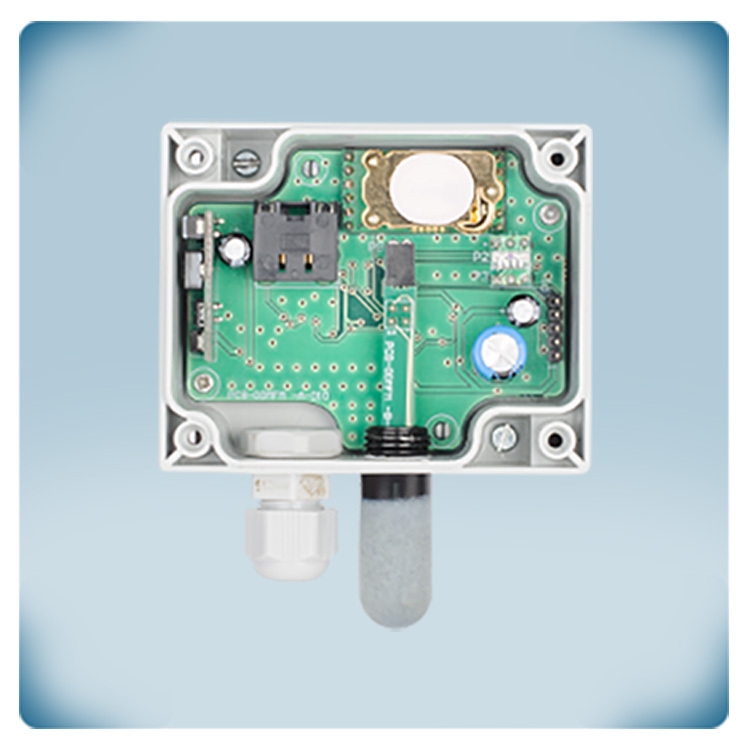

Power & Communication: The sensor operates on 24 VDC PoM (Power over Modbus), which means a single RJ45 connector provides both power and Modbus RTU (RS485) communication. A built-in bootloader allows for firmware updates.

Durability: A special coating makes the sensor resistant to both humidity and ammonia, making it highly suitable for harsh environments.

Documents

Additional specifications and description

Why is CO2 Measurement Important in Harsh Environments, and What Parameters Does This Sensor Measure?

Measuring CO2 in harsh environments or outdoors is essential for a wide range of applications related to industry, safety, environmental protection, climate research, and public health. The choice of measurement methods and equipment may vary depending on the specific needs and conditions of the application. People and animals produce CO2 or carbon dioxide while breathing. That makes CO2 concentration a good indicator for the occupancy and activity level in a space. In many applications, CO2 sensors are used as an indicator for the ventilation requirements. This HVAC transmitter measures temperature, relative humidity, CO2 and ambient light level. Based on the temperature and humidity, the dew point is calculated. All values are available via Modbus RTU communication.

How Does NDIR Technology Work in CO2 Measurement?

NDIR or Nondispersive Infrared technology is used to measure the CO2 level. This technology offers a low life-cycle cost and a precise and stable long-term operation.

Why Doesn't the Sensor Have Analog Outputs, and How is Data Read via Modbus?

This sensor does not have analogue outputs which makes it simpler and more cost efficient. All measured values are available via the Modbus input registers of this sensor. Reading the measured values is possible via SenteraWeb - our online HVAC platform, via 3SModbus software, via a BMS system or via another Modbus master device. Modbus has numerous advantages. The most important ones are that digital signals are less susceptible to interference than analogue signals and that longer cables can be used. Cable lengths of up to 1.000 meters are possible.

This sensor does not have analogue outputs which makes it simpler and more cost efficient. All measured values are available via the Modbus input registers of this sensor. Reading the measured values is possible via SenteraWeb - our online HVAC platform, via 3SModbus software, via a BMS system or via another Modbus master device. Modbus has numerous advantages. The most important ones are that digital signals are less susceptible to interference than analogue signals and that longer cables can be used. Cable lengths of up to 1.000 meters are possible. How are the Sensor's Power and Communication Connected, and What is Power over Modbus (PoM)?

This sensor can be connected with just one RJ45 connector. Power over Modbus (PoM) refers to the connection of Modbus RTU communication and a 24 V DC power supply via a single UTP cable. Modbus RTU communication makes all measured values available. To make wiring easier, we recommend using Sentera 24 V DC power supplies with RJ45 connectors. These power supplies provide short-circuit, overload, and overvoltage protection. A supply voltage of 24 V DC improves the safety and reliability of your installation.

This sensor can be connected with just one RJ45 connector. Power over Modbus (PoM) refers to the connection of Modbus RTU communication and a 24 V DC power supply via a single UTP cable. Modbus RTU communication makes all measured values available. To make wiring easier, we recommend using Sentera 24 V DC power supplies with RJ45 connectors. These power supplies provide short-circuit, overload, and overvoltage protection. A supply voltage of 24 V DC improves the safety and reliability of your installation.

What are the Sensor's Installation and Customization Options?

This sensor requires very little configuration. Once installed, it is almost directly ready to use. Temperature and relative humidity are frequently region- and season-specific. These parameters are still set to the correct values during installation. The other default settings are likely to be adequate for most applications. They can, however, be adjusted using the respective Modbus registers if necessary. The Modbus register map provides a complete overview of all adjustable settings. The temperature range, the relative humidity range or the CO2 range, for instance, can be adjusted via Modbus RTU.

This sensor requires very little configuration. Once installed, it is almost directly ready to use. Temperature and relative humidity are frequently region- and season-specific. These parameters are still set to the correct values during installation. The other default settings are likely to be adequate for most applications. They can, however, be adjusted using the respective Modbus registers if necessary. The Modbus register map provides a complete overview of all adjustable settings. The temperature range, the relative humidity range or the CO2 range, for instance, can be adjusted via Modbus RTU.

How Does the ABC Logic Self-Calibration Algorithm Work?

The ABC logic self-calibrating algorithm is by default enabled. This algorithm is designed to be used in applications where CO2 concentrations will drop to outside ambient conditions (400 ppm) at least once (15 minutes) in a 7day period, which is typically seen during unoccupied periods. The sensor will reach its operational accuracy after 25 hours of continuous operation at a condition that it was exposed to ambient reference levels of air at 400 ppm ± 10 ppm CO2.

What Are the Protection Features of the Sensor Enclosure, and How Is It Protected Against Outdoor Conditions?

This CO2 transmitter's electronic components and PCB have been treated with a coating to provide extra protection against humidity. As a result, the sensor is ideal for agricultural applications or applications requiring high humidity. In our factory, each sensor is calibrated and tested. In the unlikely event that the CO2 sensor element fails, this module can be replaced. We use high-quality sensor elements and components. This ensures the HVAC transmitter's long-term stability and accuracy. The enclosure is dust and moisture resistant to IP65 standards. It should be kept out of direct sunlight to ensure peak performance.

.webp)

.webp)

.webp)

.webp)

.webp)

.webp)

Remarks, reviews & ratings