What is the difference between a transmitter (sensor) and a sensor controller?

Sentera offers two main types of sensors: transmitters (sensors) and sensor controllers. The key difference between those two types lies in the way their outputs function.

The Sentera devices measure and/or control the following parameters: temperature, relative humidity, CO2, air quality or VOC, toxic gases (CO, NO2, LPG), ambient light, differential pressure, air volume flow or air velocity. Most sensors measure at least two parameters simultaneously.

Sentera’s sensors

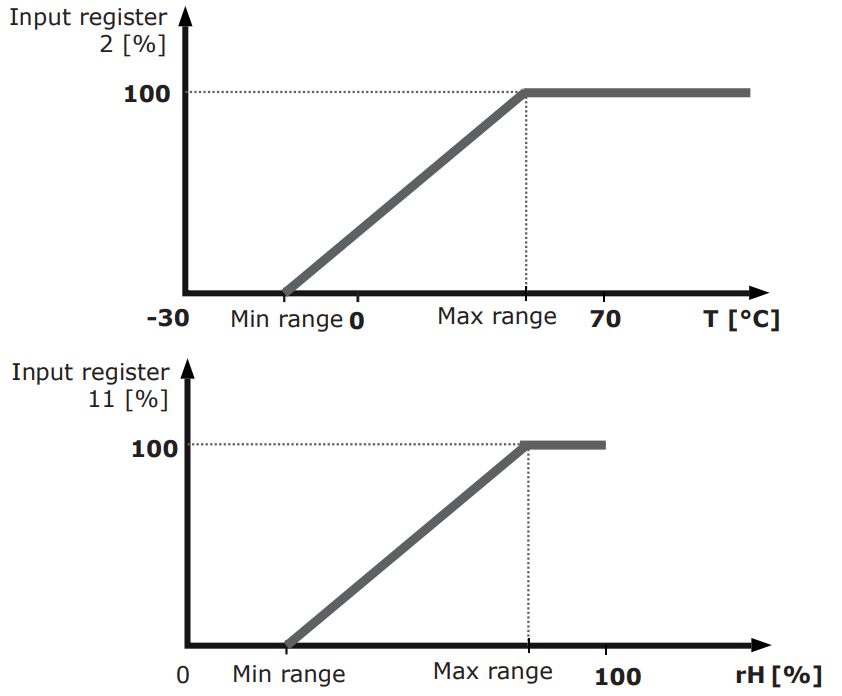

A transmitter or sensor is a device that measures a certain parameter. The device translates the measured value(s) into analogue output(s) or Modbus RTU register(s). Each measured parameter correlates with a separate analogue signal / output. The intensity of the analogue signal, expressed as a percentage, is determined by the set ranges of the measured parameters.

The Sentera sensors can be used to measure different parameters and to control an EC fan, however, the sensors cannot control directly an AC fan. In terms of measuring, it can be beneficial to know how much of a certain parameter is present in a room or to have a sensor with an alarm module. It is also possible to receive notifications via our online platform SenteraWeb whenever parameters exceed the set ranges. For users to gain access to SenteraWeb and its many functionalities, the sensor must be connected to a Sentera internet gateway.

The sensors of Sentera can regulate fan speed of EC motors directly. The user chooses one of the analogue outputs of the sensor and connects it to an EC motor. Since each analogue output corresponds to only one specific measured parameter, fan speed can be regulated in accordance with only one of the measured parameters. For instance, when using a Sentera CO2, temperature and relative humidity sensor, users can regulate fan speed based on only one of those three parameters.

Sentera’s sensors can also be used to control an AC fan indirectly in demand-based ventilation. Only one of the analogue outputs is selected to control fan speed indirectly. The analogue output is connected to a fan speed controller, which uses the transmitted signal to control an AC fan. For instance, if a Sentera temperature and relative humidity sensor is connected to a fan speed controller, fan speed is regulated based only on one of the two measured parameters.

Sentera’s sensor controllers

The sensor controllers of Sentera not only measure different parameters, but they also offer users the possibility to define a setpoint of the measured parameters. This setpoint reflects the greatest difference between this sensor type and the other. Instead of a range of values, only one point is acceptable for the sensor.

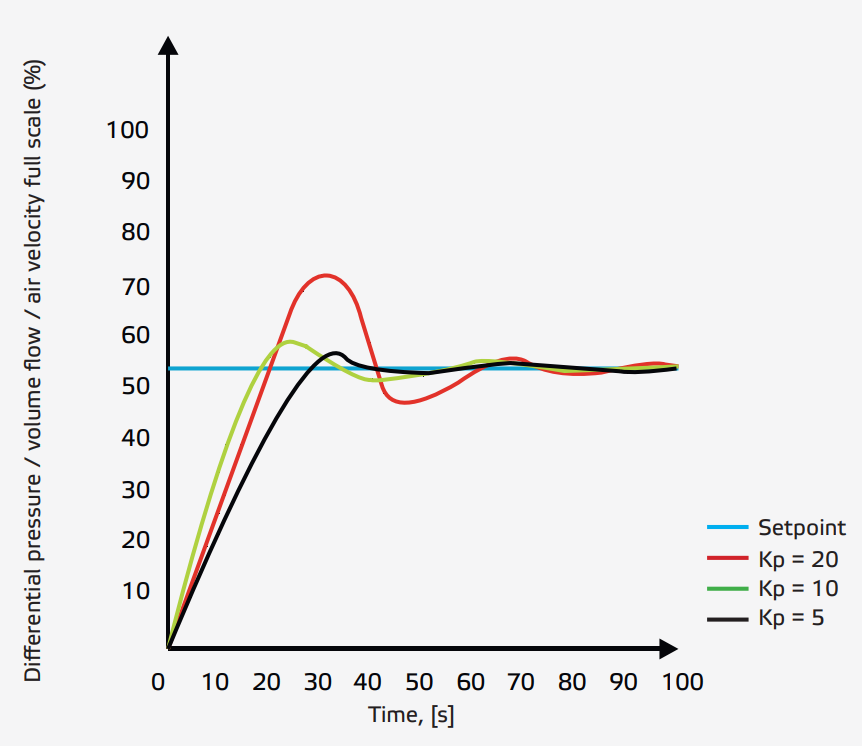

This category contains only the Sentera sensors that measure differential pressure, volume flow and air velocity. The functionality of these sensor controllers is not based on a proportional output, but on a PI algorithm. PI stands for Proportional Integral. It is a control loop which continually calculates a correction between a setpoint and the actual measurement.

The PI algorithm controls the analogue output and ensures the controlled parameter maintains its setpoint value.

For example, a Sentera differential pressure controller controls the 0–10 Volt output to maintain the differential pressure at the requested setpoint.