Dichiarazione di conformità UE

Convertitore di Frequenza | 30 A | 7,5 kW | IP66 | Trifase 230 V

Descrizione del prodotto

Convertitore di frequenza variabile con potenziometro incorporato, interruttore di marcia e sezionatore di rete. Controlla ventilatori o pompe centrifughe con motori trifase da 230 Volt in applicazioni HVAC. Questo inverter richiede un'alimentazione trifase a 230 Volt.

La corrente massima (combinata) del motore è di 30 A. Questo inverter controlla diversi tipi di motori trifase da 230 Volt, ad esempio: IE3, IE4, motori a magnete permanente, brushless DC o a riluttanza sincrona. Questo azionamento può essere controllato completamente tramite i pulsanti integrati sul pannello frontale. È sufficiente collegare l'azionamento, ruotare il potenziometro incorporato e il motore inizierà a funzionare.

Il contenitore è a tenuta di polvere e predisposto per il lavaggio. Offre una protezione IP66 contro l'ingresso di sporco e acqua. Il dissipatore è resistente alla corrosione. Il filtro EMC integrato è di Classe C1.

Codice produttore: ODE-3-420300-3F4B

Documenti

Specifiche e descrizioni aggiuntive

La combinazione di un inverter trifase e di un motore trifase è generalmente più efficiente e pratica rispetto a una variante monofase. Una tensione di rete trifase di 230 Volt non è così comune nelle installazioni industriali, ma piuttosto negli ambienti residenziali. Ciò rende questo inverter estremamente adatto al controllo di ventilatori o pompe in applicazioni HVAC. Inoltre, è estremamente facile da usare. In molte applicazioni, le impostazioni predefinite possono essere mantenute e l'inverter può essere messo in funzione subito dopo l'installazione.

Un regolatore di velocità variabile del ventilatore regola solo la tensione del motore. Un inverter controlla anche la frequenza del motore oltre alla tensione del motore. Da un lato, il vantaggio di un controllo ottimale del motore e di un funzionamento più efficiente dal punto di vista energetico. Dall'altro, il costo più elevato e la necessità di impostare alcuni parametri necessari prima della messa in servizio. La possibilità di controllare la tensione e la frequenza del motore offre ulteriori opzioni di controllo e quindi ulteriori parametri. Per rendere il dispositivo il più semplice possibile, sono state create delle macro funzioni applicative. Le impostazioni principali sono raggruppate in 14 parametri di base, riportati nella scheda di aiuto contenuta nell'involucro.

Il contenitore per il montaggio a parete è progettato per proteggere l'elettronica in ambienti difficili e in applicazioni esterne. Offre una protezione IP66 contro l'ingresso di acqua, sporco e agenti contaminanti. Ciò consente di installare il convertitore di frequenza direttamente sull'impianto, anche in applicazioni di lavaggio. Elimina la necessità di un quadro elettrico. Si consiglia di proteggere il dispositivo dalla neve e dalla luce solare diretta.

Selezionando una di queste macro applicative, le impostazioni più importanti vengono preconfigurate automaticamente. In questo modo si risparmia di definire la funzionalità dei diversi ingressi. Queste funzionalità sono predefinite nelle macro applicative. Offrono la soluzione ideale per il risparmio energetico quando non è richiesta un'elevata coppia di spunto. Le applicazioni tipiche sono ventilatori AC, soffianti, pompe centrifughe, estrattori di fumi e regolatori di flusso d'aria.

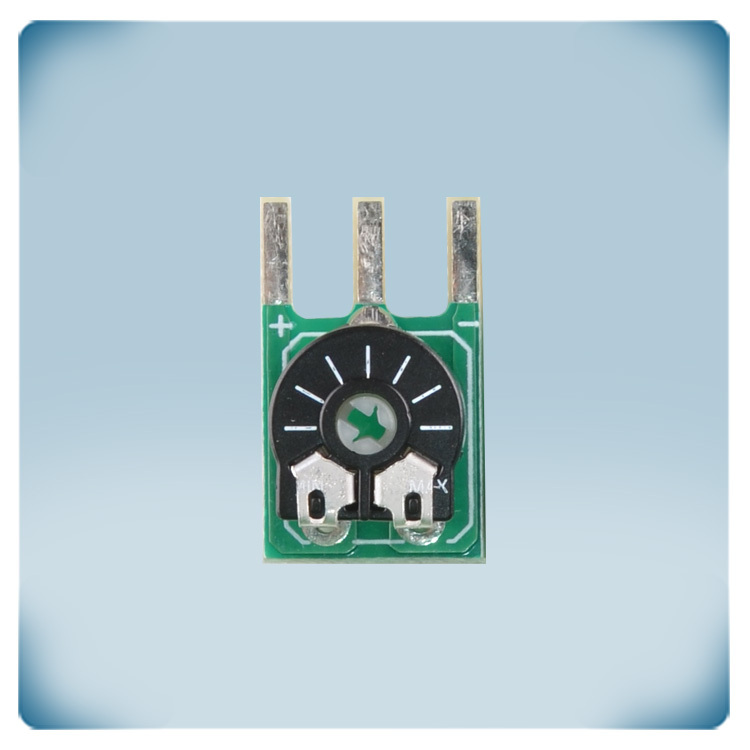

Per impostazione predefinita, l'ingresso 1 viene utilizzato per avviare il motore. Un potenziometro opzionale da 10K può essere collegato ai terminali 5, 6 e 7 per regolare la velocità della ventola.

Quando l'ingresso 3 è attivato, il motore funziona alla velocità predefinita nel parametro 20. Quando l'ingresso 3 non è attivato (o non è collegato), la velocità del motore può essere regolata tramite il potenziometro esterno (o il segnale di controllo analogico).

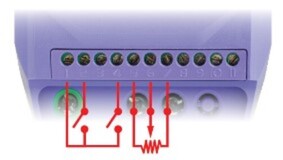

Un esempio di applicazione

Questo esempio di applicazione spiega come controllare la velocità del ventilatore. T1 è per l'alimentazione a 24 V di T2 e T4. Il contatto sinistro (T2) avvia/arresta il ventilatore. Quando il contatto destro (T4) è chiuso, il ventilatore funziona alla velocità fissa predefinita (regolabile nel parametro 20). Quando il contatto destro è aperto, la velocità del ventilatore può essere selezionata manualmente tramite un potenziometro da 10K o regolata in base alla domanda tramite un sensore HVAC (segnale 0-10 Volt). Lo schema di cablaggio a destra mostra il collegamento di un potenziometro 10K. T5 serve per l'alimentazione a 10 V nel caso in cui sia collegato un potenziometro 10K, mentre T6 e T7 possono essere utilizzati per selezionare la velocità del ventilatore tramite un segnale analogico. Una volta terminato il cablaggio, si inseriscono le specifiche del motore collegato nei parametri 1 - 10. Il motore può ora essere avviato! A questo punto il motore può essere avviato!

I convertitori di frequenza controllano la tensione e la frequenza del motore attraverso una tecnologia chiamata modulazione di larghezza di impulso. Questa tecnologia converte la tensione alternata in tensione continua. Un inverter è dotato di un bus CC, che può essere visto come un serbatoio tampone per l'energia disponibile. Questo serbatoio tampone viene riempito sia dalla tensione di alimentazione (tramite il raddrizzatore) sia dall'energia rigenerativa del motore che rifluisce durante la frenata. Questa tensione continua viene riconvertita in una sorta di tensione alternata dagli IGBT. Gli IGBT, o transistor bipolari a gate isolato, sono transistor bipolari con un terminale di gate isolato in grado di commutare correnti elettriche elevate ad alta velocità. Grazie al controllo intelligente degli IGBT, è possibile controllare sia la tensione che la frequenza del motore. Ciò consente un controllo ottimale del motore e un funzionamento efficiente dal punto di vista energetico.

Filtro EMC integrato standard di classe C1

Uno svantaggio degli IGBT a commutazione ad alta frequenza è il fatto che inquinano la rete elettrica con segnali di interferenza armonica più elevati (inquinamento EMC). Per ridurre al minimo questo inquinamento della rete, è integrato di serie un filtro EMC di classe C1. Questo inverter è inoltre dotato di un chopper di frenatura integrato. In questo modo è possibile collegare una resistenza di frenatura per ridurre il tempo di decelerazione, se necessario. I sensori HVAC Sentera possono essere collegati tramite l'ingresso analogico o tramite comunicazione Modbus RTU.

Osservazioni, recensioni e valutazioni