EU declaration conformity

Temperature sensor | stainless steel probe 165 mm | PoM 24 VDC

Product description

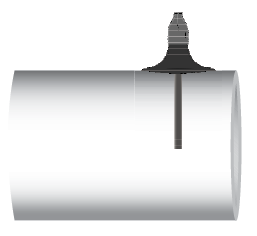

The DTS-M series consists of digital temperature sensors and transmitters designed for temperature monitoring in air ducts. They are powered by 24 VDC over Modbus (PoM).

These sensors measure temperatures from -30 to 70 °C using a 165 mm long stainless steel probe. The temperature data is transmitted via Modbus RTU communication.

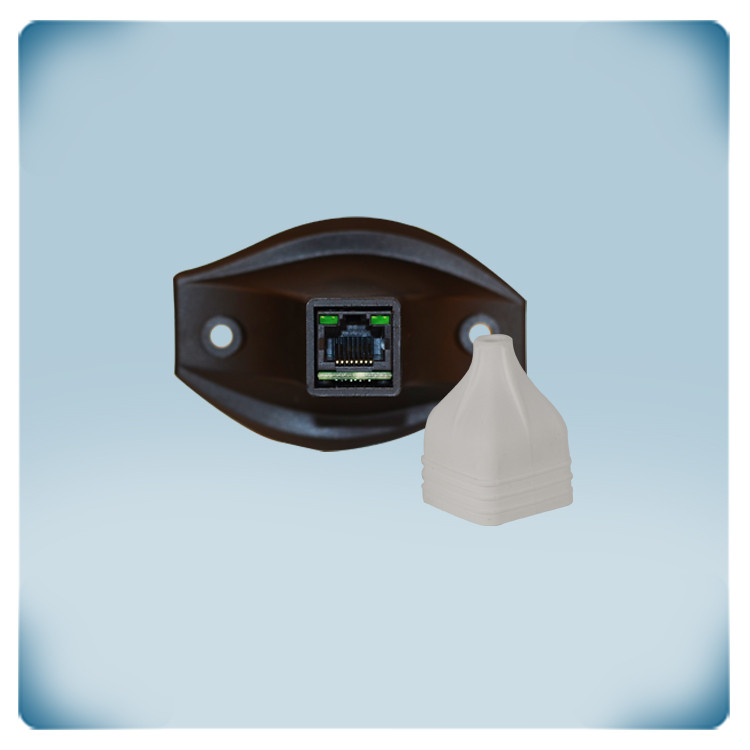

Wiring is simplified through a single RJ45 socket, which handles both power and Modbus RTU connections. The durable, low-maintenance, and easy-to-clean design has an IP65 protection standard. The sensors are ideal for reliable temperature control systems, operating in temperatures from -30 to 70 °C and relative humidity of 5 to 95% rH (non-condensing).

Documents

Additional specifications and description

How Should the Temperature Sensor Probe Be Installed for Optimal Performance?

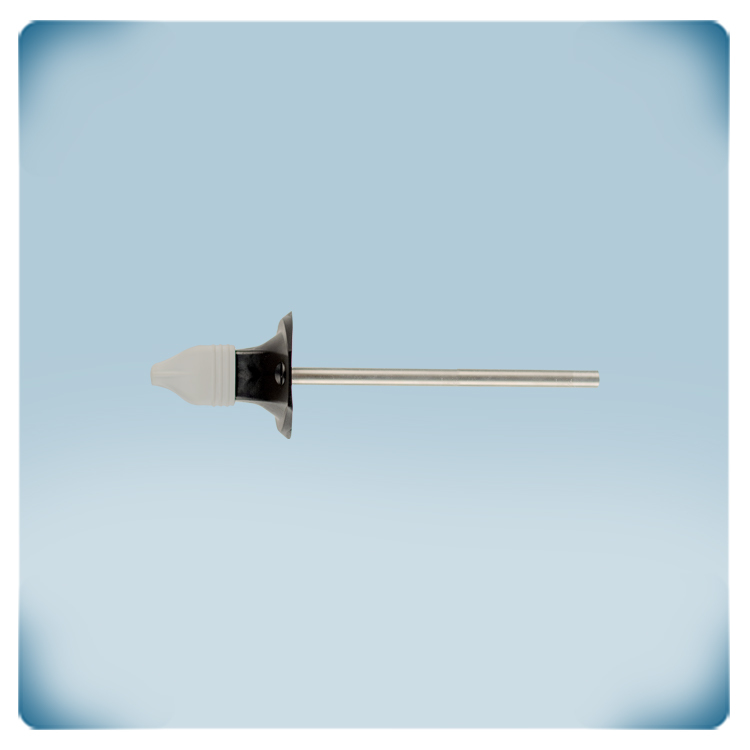

This temperature sensor has a metal probe with a length of 165 mm. To ensure optimal performance, the sensor must be installed in a zone without turbulences.

How Are Power and Communication Connected to the Sensor?

Both power supply and Modbus RTU communication can be connected via the RJ45 socket. The measured temperature can be read out via Modbus RTU.

What Are the Key Features of the Sensor Probe's Design?

The metal probe of the sensor is inserted in an air duct. The metal probe has a smooth, closed surface. This simplifies cleaning of the air ducts.

How Can the Sensor Be Mounted and Used to Address Temperature Stratification?

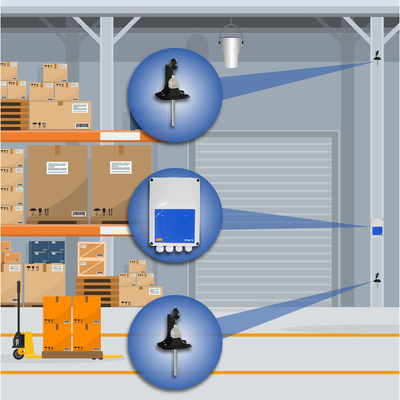

Thanks to the specially developed mounting bracket this sensor can be installed on a wall or any other surface. Mounting two temperature sensors at different heights on a wall is an effective way to monitor and manage temperature stratification in a space.

Temperature Stratification occurs when warmer air rises and cooler air settles near the floor. This creates a temperature gradient within the space, which can lead to inefficient heating or cooling. By measuring the temperature difference between the two sensors, you can assess the degree of stratification. The higher sensor is mounted near the ceiling and measures the warm air that naturally rises. The lower sensor is mounted closer to the floor and tracks the cooler air.

The sensors can be integrated into a building HVAC control system. If the difference between the two temperatures exceeds a set threshold, the system can trigger destratification equipment, such as ceiling fans or air recirculation units, to mix the air more evenly.

Depending on the type of your fan you can choose between Sentera’s EC fan speed controllers or AC fan speed controllers, which will analyse the data and control the fans on-demand based on the DTS sensors readings.

Thanks to the specially developed mounting bracket this sensor can be installed on a wall or any other surface. Mounting two temperature sensors at different heights on a wall is an effective way to monitor and manage temperature stratification in a space.

Temperature Stratification occurs when warmer air rises and cooler air settles near the floor. This creates a temperature gradient within the space, which can lead to inefficient heating or cooling. By measuring the temperature difference between the two sensors, you can assess the degree of stratification. The higher sensor is mounted near the ceiling and measures the warm air that naturally rises. The lower sensor is mounted closer to the floor and tracks the cooler air.

The sensors can be integrated into a building HVAC control system. If the difference between the two temperatures exceeds a set threshold, the system can trigger destratification equipment, such as ceiling fans or air recirculation units, to mix the air more evenly.

Depending on the type of your fan you can choose between Sentera’s EC fan speed controllers or AC fan speed controllers, which will analyse the data and control the fans on-demand based on the DTS sensors readings.

.webp)

.webp)

.webp)

Remarks, reviews & ratings