Power supplies

What is a power supply?

When prompted with such a query, the typical response revolves around defining a power supply module as a device connected to the mains that energizes other devices. In essence, its primary function involves the intricate process of transforming raw alternating current (i.e. 230 VAC) from the mains – usually compatible with global supply voltages, accounting for tolerances, dips, and spikes – into a lower DC or AC voltage.

Simply put, power supplies are devices intended for transformation of the mains voltage (the voltage coming from the electrical network (DC or AC)) into voltages of other classes for powering electronic devices. Power supplies can be external (in the form of separate modules) or integrated in electronic devices and being their integral part.

Key attributes of a well-designed power supply module include the ability to maintain a constant output voltage despite variations in input voltage and load current. Rapid load changes are swiftly addressed within the designed control loop response time, minimizing consequential output voltage transients. Moreover, the module ensures safety isolation at the highest statutory level for standard mains voltages, maintaining a safe threshold even in the event of a single component failure.

A high quality design also considers factors such as controlled radiated and conducted noise emissions, adhering to statutory levels, and immunity to external noise sources. Furthermore, the module incorporates multiple layers of protection against internal faults, mitigating risks of output over-voltage, component failures, excessive temperatures, electric shock or potential fire hazards. Sentera offers power supplies as separate modules to power devices that need low input voltage, for example Sentera’s sensors, transmitters and controllers.

Despite the mundane design of a power supply unit, there is significant merit in understanding its internal components and the crucial role they play in isolating potentially lethal mains voltage from user-accessible connections. Appreciating the intricacies of a power supply is particularly noteworthy when considering the potential consequences of malfunctions, as it extends beyond mere inconvenience to potential risks for the connected equipment, such as an expensive appliance, and, most importantly, the irreplaceable human operator.

The internal workings of a power supply unit serve as a critical barrier, safeguarding users from direct exposure to hazardous mains voltage. The appreciation for this internal insulation underscores the importance of reliable design and quality components within the power supply. In the event of a malfunction, the ramifications can extend beyond mere inconvenience. A faulty power supply has the potential to jeopardize the integrity of connected equipment, leading to significant financial losses, especially in the case of expensive transceivers. Moreover, the safety of the human operator, an irreplaceable asset, is paramount and can be compromised in the event of power supply failure.

Power supply types

Sentera offers two types of power supply modules: switch mode power supplies (SMPS) and linear power supplies (LPS) or safety transformers.

Linear VS switch-mode power supplies

Widely applied everywhere in technical equipment for many decades, the LPSs are rather simple and even primitive devices. Unlike LPSs, SMPSs are much more complex devices working at high frequency and consisting of numerous active and passive elements.

The first switch-mode power supplies (SMPS) were released in the late 1960s and, since then, these devices have been intensively developed until today. The SMPS has almost entirely replaced the older linear power supply (LPS) from most areas of technology. Both linear and switch-mode power supplies are devices that convert electrical energy to provide a stable output.

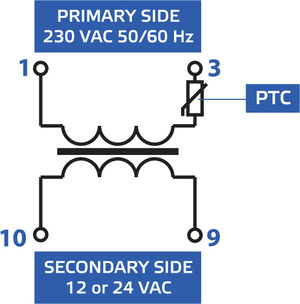

In the context of mains-operated power supplies, a ‘linear’ type uses a 50 – 60 Hz transformer to isolate and convert the AC mains voltage down to a lower level. A transformer is a component that consists of two coils with wire wound around a magnetic core. When an AC current flows through the primary winding, it creates a changing magnetic field, which induces a current in the secondary winding. The number of wire turns in each winding determines the attenuation or amplification factor. For example, you could convert 230 VAC into 12 VAC by choosing the right transformer. A transformer is quite a heavy component and this needs to be considered depending on the intended use.

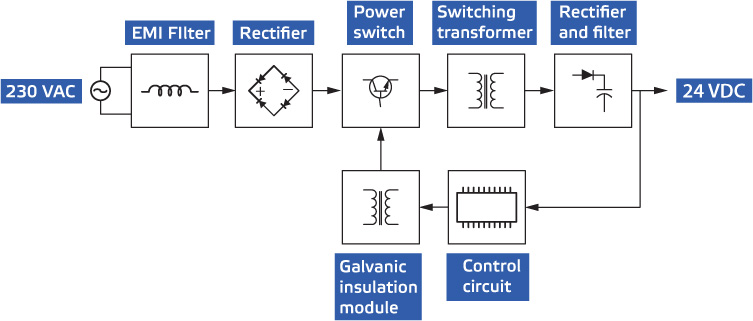

A ‘switched-mode’ mains power supply (SMPS) normally rectifies the mains directly to produce high voltage DC. This is then ‘chopped’ and passed through a high frequency transformer, which provides isolation and conversion down to a lower voltage level, where it is rectified and filtered. Regulation is typically achieved by varying the duty cycle of the chopping action.

Are switch-mode power supplies superior to their linear counterparts?

Using optimized technology, switching power supplies are suitable for most applications. A linear power supply can only produce a voltage lower than the input voltage. All linear regulators require the input voltage to be at least a minimum amount above the output voltage. This is called the drop-out voltage. The drop-out voltage is the parameter that drives the calculations for efficiency and worst-case power dissipation.

However, switching supplies are not always the best solution. Although a switched-mode supply can be much more efficient than a linear one but its downside is the noise it produces. High frequency noise is an inherent part of the output of a switching power supply. Linear supplies can be many times quieter than SMPSs. A linear supply is usually a requirement for very noise sensitive analog circuits. Where maximum efficiency is required, modern systems will frequently pre-regulate a voltage with a switch-mode supply to a value just above the drop-out voltage and use a linear supply to provide the low noise power to the analog circuits. Another disadvantage of switching supplies is that they typically need longer recovery time from a large step change in load current or a step change in input voltage when compared with linear supplies. Linear supplies are usually a better solution for very low power applications.

The switch-mode power supply repeatedly turns the switch on and off at high speed. This causes noise owing to switching. Linear power supplies produce less noise than switching power supplies, thanks to the transformer technology used.

In a linear power supply, the frequency input from an outlet or another source is input directly to the transformer, whereas in a switching power supply, the current after rectification is sent to the transformer as a high-frequency pulse. As far as energy efficiency is concerned, SMPSs provide high energy efficiency. A switching power supply unit is more efficient because a linear power supply loses more energy as heat. On the other hand, linear power supplies respond faster to load fluctuations since they are controlled by the response of the regulator circuit unlike the output of the switching power supplies. Therefore, as power consumption increases, the total cost of the switch-mode power supply becomes less than that of a linear power supply.

In summary, the choice between linear and switch-mode power supplies depends on the specific requirements of the application. Linear power supplies are favoured for their precision and low noise, while switch-mode power supplies excel in efficiency, compactness, and weight savings. The decision often involves balancing these factors based on the priorities of the intended use.