Speed control for single phase motors - 230 VAC supply

Single-phase and three-phase supplied frequency inverters both serve the purpose of controlling motor speed, but each has its own set of advantages. The key advantage of single-phase supplied frequency inverters is their versatility in installations where only a single-phase power supply is available. Many residential and small-scale applications rely on single-phase power sources, making these inverters suitable for a broader range of scenarios.

Single-phase frequency inverters are particularly advantageous for powering smaller motors used in household appliances, fans, and light industrial equipment. They offer a cost-effective and space-saving solution for applications with limited power requirements. However, it's important to note that single-phase systems may have limitations in terms of power capacity compared to their three-phase counterparts.

In contrast, three-phase supplied frequency inverters are commonly used in industrial settings with larger motors and higher power demands. They are more energy-efficient and provide smoother operation for heavy-duty machinery. While single-phase inverters offer versatility, three-phase inverters are better suited for demanding industrial applications where robust power delivery and efficiency are critical. Ultimately, the choice between single-phase and three-phase frequency inverters depends on the specific requirements, such as motor specifications and available power sources of the intended application.

Different enclosure types

FI-E11 frequency inverters are available in an IP20 enclosure and an IP66 version. The choice between both enclosure types depends on the environmental conditions and the specific application.

IP20 enclosures should be installed in an electric cabinet. They are suitable for indoor environments where the electrical equipment is protected from dust and limited moisture exposure. They are cost-effective and allow for easy access to the internal components for maintenance or adjustments. These inverters are ideal for controlled environments where the risk of water and dust ingress is minimal.

IP66 enclosures offer a higher degree of protection against harsh environmental conditions. They are dust-tight and provide complete protection against powerful water jets, making them suitable for outdoor use or locations with high levels of dust and moisture. The sealed design prevents damage from external elements, ensuring the reliability and longevity of the frequency inverter in challenging settings. However, to ensure sufficient cooling and heat dissipation, it is important to protect them from direct sunlight.

How to control the frequency inverter?

All FI-E versions can be controlled via the inputs or via the buttons on the front panel. A digital signal can be used to generate a start / stop command while an analogue control signal can be used to define the requested motor speed.

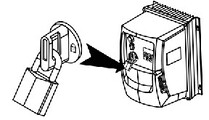

FISE series feature IP66 enclosure and integrated controls. Motor speed can be regulated manually via the potentiometer on the front panel and the motor can be started, stopped and inversed via the 3-position switch on the front panel. The 3th knob on the front panel is a mains switch with padlockable OFF position. This makes it possible to ensure safe working conditions while performing maintenance tasks and to cut the motor off from the electrical grid.